-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Notice Board

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Terms of Website Use

- Notice Board

- Survey

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

Corrosion Management Plan and Framework

Corrosion Management Plan and Framework

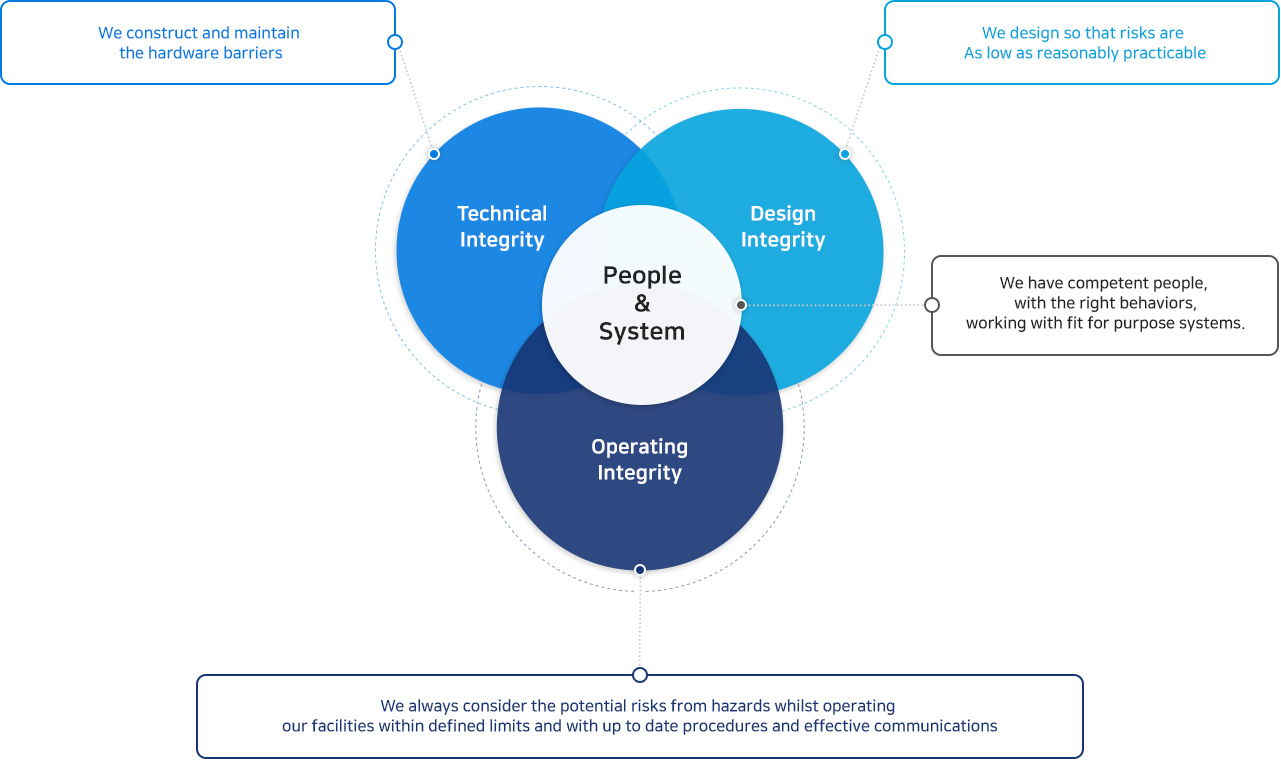

Our Corrosion Management Plan and Framework will defines the policies, standards, procedures, practices, responsibilities, authorities and resources that shall be in place to ensure that corrosion management satisfies the integrity objective.

It provides a structured framework for the identification of the common threats associated with corrosion (and other common material degradation mechanisms) and the selection, installation and maintenance of suitable common corrosion barriers to control those threats.

A potential loss of integrity derives from the fact that facilities are exposed, both internally and externally, to corrosive environments. egradation/corrosion threats shall, therefore, be identified, quantified and controlled to safeguard technical and operational integrity throughout the life of the asset.

A potential loss of integrity derives from the fact that facilities are exposed, both internally and externally, to corrosive environments. egradation/corrosion threats shall, therefore, be identified, quantified and controlled to safeguard technical and operational integrity throughout the life of the asset.

-

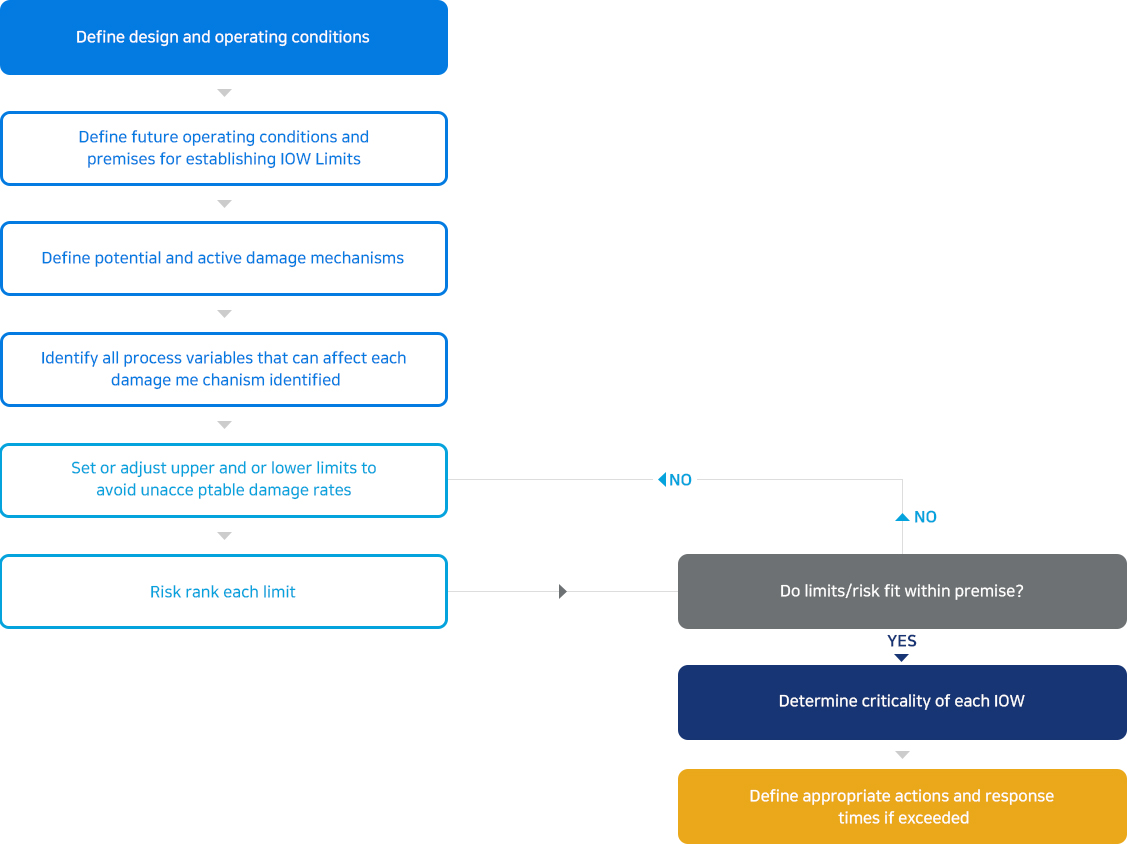

Risk, Type of IOW, IOW guidance/Action 등의 내용을 포함하고 있는 표입니다. Risk Type of IOW IOW guidance/Action High Critical IOW’s Required - Limits and durations established on all IOW process parameters for monitoring;

IOW’s are alarmed/alerted and SME’s are notified of exceedances;

Operations take urgent predetermined action to return process to normal operation.

If exceed, could lead to rapid deterioration of process equipment and need an immediate action.Medium High Critical or Standard IOW’s Required - Limits and durations established on all IOW process parameters for monitoring;

IOW’s are alarmed/alerted and SME’s are notified of exceedances;

Operations take predetermined action to return process to normal operationMedium Standard or Informational IOW information Limit (IIL) identified - IOW’s identified suggested limits specified for each IOW;

Operations and SME’s are alerted/notified of exceedances;

Troubleshooting initiated with

planned adjustments to operations, inspection/maintenance developed.

If exceeded over a specific time frame, could cause increased of

corrosion rate and need to identity the time to reduce the corrosion rate by a chemical injection etc.Low Informational IOW information Limit (IIL) suggested - Normal operating parameters identified for analysis;

Parameters tracked and trended by SME to determine long-term effects on equipment reliability.

Generally to predict the long term integrity of equipment, do not typically require operational

responses but maybe utilized to assess fufure repair during turnaround and shutdown frequencies.