-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Notice Board

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS KR-PILOT KR-POWER EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Terms of Website Use

- Notice Board

- Survey

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS KR-PILOT KR-POWER EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

Introduction

Asset Integrity Sustainability and Management System (AISMS)

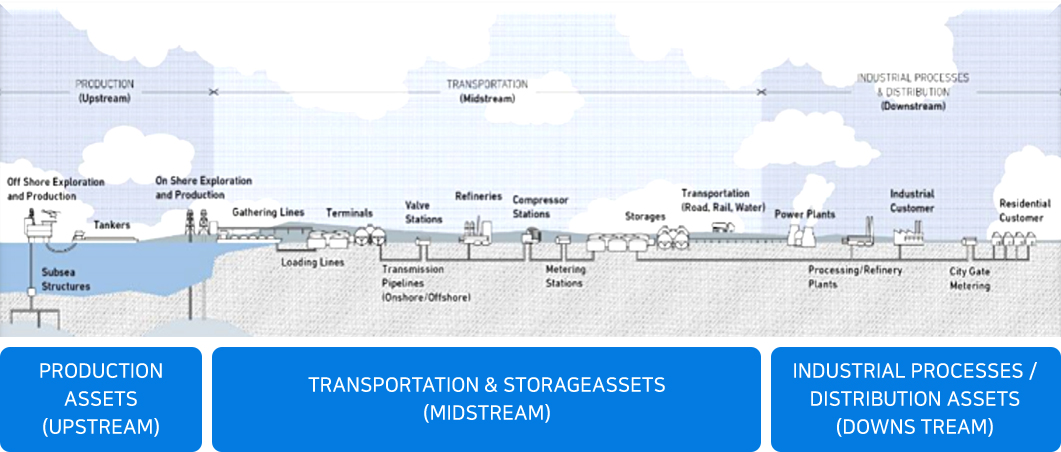

Asset Integrity Sustainability and Management System (AISMS) is systematic and coordinated activities and practices through which an organization optimally and sustainably manages its asset and assets system their associated performance risk and expenditures over their life cycles for the purpose of achieving its organizational strategic plan. The AISMS drives the overall performance of physical asset resulting in improved safety, availability, reliability, productivity and profitability.

Managing integrity concerns the application of qualified standard, by competent people, using appropriate processes and procedures throughout the asset life cycle, from engineering and design, construction, operation, inspection, and finally to repair/replacement when necessary. The objective is to roactively ensure that the asset performs its functions as intended, or when the asset performance falls below the intended level, effective correction and corrective action are promptly implemented.

Included in the objective of managing integrity, is the prevention of any adverse impact on people (health and safety), environment, asset and reputation (PEAR) as a result of the functional failures of the asset, while maintaining focus on business.

-

Digitalisation of Integrity Management and Data Management

- - Risk Based Inspection and Asset Integrity Management Software (NIMA)

- - Online Integrity Assessment Database and Inspection Reference Plan Management

- - Online Database Management (Digitalisation) ? AR, VR, Mobile Support & Digital Twin Integrated PIM

-

Integrated Inspection and Integrity Management Capabilities

- - Non-Intrusive Inspection (NII) Technique

- - Drone with 3D model

- - Advanced DUI / ROV

- - Advanced Inspection and Special Scheme of Inspection

-

Certification, Accreditation and Global TPI

- - Regional and international TPI services

- - Offshore and onshore TPI services (EPCC, Design, Eng. & Operational Phase)

- - Lifting equipment management and inspection

- - Quality Management Services

-

AISM Diagnostic and Audit

- - FFS / FFP Assessment and Consultation

- - FEA and Stress Analysis

- - Laboratory Services and Testing

- - Subject Matter Expert (SME) Consultation

-

Advanced and Specialist Assessment

- - Corrosion Management Framework

- - FMECA and RCFA Studies

- - Focused Scheme of Inspection and Mechanical Integrity Studies

- - Risk Assessment Studies

-

Cost Effectiveness and Optimization

- - Manpower Optimization for the field works

- - Zero / Minimum Reworks and On-time Deliverables

- - Accurate and Efficient Decision Making

- - Expertise, Qualified and Authorized Personnel

KR(B) AISMS exists to assist the organization in archiving its business objective and thus contributes significant value to a client/user in following:

- - Systematically analyze asset objectives, asset risks and hazard, asset performance, and integrity leadership behaviors to identify drivers needed for asset integrity improvement.

- - Examine scope and execution of the integrity programs to identify scope of optimization and execution effectiveness and efficiency improvement opportunities.

- - Identify Asset Integrity simplification opportunities that will help asset owners to better alignment of efforts to risk and effectively execute programs at the workplace.

- - Effectively and efficiently mitigate higher consequences safety Health, Environment, Security public disruption and business critical events arising from failure of critical equipment or system.

- - Optimizes the costs of inspecting, testing and managing the physical assets

- - Provides a basis for safely extending the life of critical physical assets, eliminating or deferring their replacement