-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Notice Board

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

-

About us

- About KR CEO KR History KR's Services Mission & Vision CI Organization

- Careers The Right People Job Location Recruitment

- Business Sustainability ESG Management Anti-Bribery Management Quality Management Health/Safety/Environment

- PR Center Digital News Room Publications PR Video Events Webzine

- Terms of Website Use

- Notice Board

- Survey

-

Our Services

- Classification During Construction Introduction About KR EDAS KR EDAS Log in After Construction Introduction Transfer of Class and Certification KR Remote Survey Introduction Types of Remote Survey Survey application FAQ Existing Ships Condition Assessment Program PSC PSC Introduction PSC Information PSC Deficiency Data PSC Check List PSC Regional MOUs PSC Annual Report PSC Link Detention Notice USCG/PARIS MoU Information LNG LNG Carrier LNG Fueled Ship LNG Bunkering Ship Oil Major Inspection Overview OCIMF Annual Report Technical Information Link

- ISM/ISPS/MLC ISM ISPS MLC

- Statutory Services Statutory Survey Foreign Governments Status of Authorization KR at IMO

- Approval of Class Equipment General Scope Approval of Manufacturing Process Type Approval Design Approval Procedure Flow Chart of Marine & Ocean Equipment Approval Flow Chart of Design Approval Documents e-MESIS Approval Lists EU RO-MR Introduction Application Form Documents to be Submitted Approval List

- Cyber Security Certification Service Certification Service Ship & Company Certification Cyber Security Type Approval Software Conformity Certification Technical Service Awareness Training Newsletter International Response

- Certification System Certification Third Party Inspection Global Certification AIP(Approval In-Principle) Introduction Procedure Track Record Renewable Energy Lender’s Technical Advisor for renewable energy Wind Energy

- Naval Service NSAP Rules and standards for naval vessels Core technology and technical support

- Oil & Gas Asset Integrity Sustainability and Management System(AISMS) Introduction Integrated Integrity Management System (IIMS) Integrity Diagnostic and Data Management Corrosion Management Plan and Framework Quality Assurance, Control and Surveillance Digitalization and Paperless Inspection Scheme Global Third Party Inspection Network

- Service Supplier SeaTrust - TM Service Supplier Download Service Supplier Search

- Customer Services Register of Ships EU Ship-info Useful Links

- Online Application Introduction Application Form On-line Application Service On-line application for ISM/ISPS & MLC Application Status

-

Decarbonization & Digitalization

- Decarbonization KR Decarbonization Portal KR Decarbonization Magazine

- Digitalization Smart & Autonomous Ship AI Driven Inspection Condition Based Inspection Digital Twin

- Digital Solutions KR-DAON KR e-Fleet e-Cert Introduction Flag Acceptance User Guide FAQ KR e-Fleet EACSD e-Cert Verification e-MESIS KR-CON Fit-For-Purpose Key Functions Order Online KR-NBM KR-EDAS EACSD KR GEARs SeaTrust Software KR-ERS About KR-ERS Flow Chart for KR-ERS Service Registration KR-SteelCoil About KR-SteelCoil KR-SteelCoil Program

-

Rules & Solutions

- Classification Technical Rules Classification Technical Rules Service Establishment and amendment history of Classification Technical Rules Circulars Guidelines External opinion inquiry on the amendment Part 1, Forms (Survey Programme etc)

- Information & Updates Briefings of IMO SOLAS/MARPOL/Others Port Rule Information ISM/ISPS/MLC SOPEP/SMPEP Rules and Technical Information

- Hull Technology Research Seakeeping Hydrodynamics R&D related to CCS Arctic Technology KR Rules & Guidance on Hull Structures Application Technologies

- Engineering Offshore Platform Commercial Ship Naval Ship

- System Risk Assessment R&D Activities on Risk Assessment Risk Assessment

LNG Carrier

-

-

What is LNG?Generally, natural gas means the naturally occurring inflammable gas, of which the main ingredient is hydro-carbon, Methane (CH4) forms the highest proportion in LNG - generally the larger the molecule, the smaller the percentage volume. Natural gas is condensed into a liquid at close to atmospheric pressure by cooling it cryogenically (to about -162℃). LNG is highly flammable and exposure would cause an accident, as a result, LNG carriers (LNGC) have been developed to be technologically complex, highly specialized ships.

What is LNG?Generally, natural gas means the naturally occurring inflammable gas, of which the main ingredient is hydro-carbon, Methane (CH4) forms the highest proportion in LNG - generally the larger the molecule, the smaller the percentage volume. Natural gas is condensed into a liquid at close to atmospheric pressure by cooling it cryogenically (to about -162℃). LNG is highly flammable and exposure would cause an accident, as a result, LNG carriers (LNGC) have been developed to be technologically complex, highly specialized ships.

-

-

-

Expansion of LNG production and increase of LNGCLNG production sharply increased following the shale revolution, the largest energy revolution in 21st century. Shale gas has made America transition from an importing country to an exporting one, furthermore America’s multilateral trade has seen demand for LNGC steadily increase.

Expansion of LNG production and increase of LNGCLNG production sharply increased following the shale revolution, the largest energy revolution in 21st century. Shale gas has made America transition from an importing country to an exporting one, furthermore America’s multilateral trade has seen demand for LNGC steadily increase.

-

-

-

Registered LNGC in KRKR is trusted Class society, with more than 30 years of LNGC survey experience.Today the society surveys 35 registered LNGCs (2020.01.01), a number that will increase when the vessels being surveyed during construction go into operation.

Registered LNGC in KRKR is trusted Class society, with more than 30 years of LNGC survey experience.Today the society surveys 35 registered LNGCs (2020.01.01), a number that will increase when the vessels being surveyed during construction go into operation.

-

-

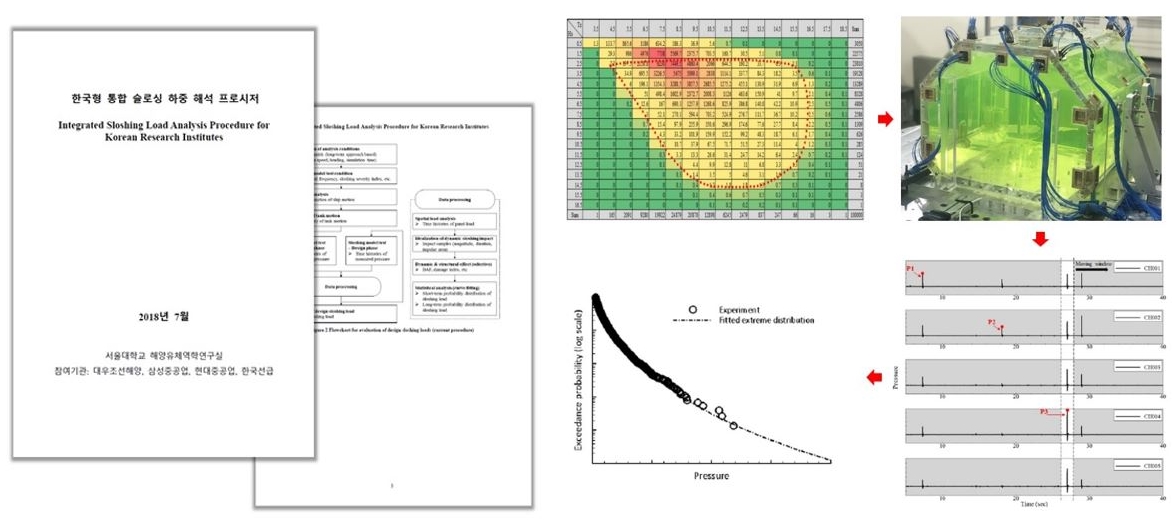

Researching and development work for LNGCKR is not complacent, we are working on a range of projects and research in conjunction with Korean shipyards, to provide a range of expert options and choices for LNGC shipowners.It is well known that sloshing is one of the key technical issues for LNG Cargo Containment Systems (CCS). Various approaches can be used to estimate the sloshing load, but due to the strong nonlinearity of the sloshing phenomenon, the model test is accepted as the most reliable approach.Most classification societies have their own test-based procedure to estimate design sloshing load. KR has established an “Integrated Sloshing Load Analysis Procedure for Korean Research Industries” working with Korean research institutes (SNU, DSME, HHI, SHI). It complies with both the classification societies guidelines and Korean industrial processes, and offers a way to validate and improve on established procedures, the validation test is now underway.KR signed a MOU with Hyundai Mipo Shipyard to develop small and medium size LNGC incorporating B type cargo tanks. The B type tank offers a better use of space than a C type tank which is generally better suited to small size LNGC. The B type tank therefore allows the shipowner to increase cargo load capacity and freight income.KR has amended its existing structural rules for membrane type LNGC and developed new rules that apply the EDW (Equivalent Design Wave) concept. Based on this, KR signed an MOU with the Korean shipyard with the best LNGC construction skills to develop 170K membrane type LNGC key plans. Through this project, we will develop a KR mother ship plan for membrane type LNGC for each Korean Shipyard, and will provide more an extensive range of options for ship owners.