-

- Notice for Amendments to KR Classification Technical Rules (Pt 9 Ch 2 of Rules/Ch 16 of Guidance for LFFS)

- Notice for Amendments to KR Classification Technical Rles (Rules & Guidance for Classification of Ships Using Low-flashpoint Fuels)

- Notice for Establishment to the KR Technical Rules(Guidance for Photovoltaic Systems Onboard Ships)

- Fire Safety of RO-RO Passenger Ships in Service

- (2025-IMO-11) LNG Bunkering Manifolds

- Notice for Amendments to KR Classification Technical Rules (Pt 9 Ch 2 of Rules/Ch 16 of Guidance for LFFS)

- Notice for Amendments to KR Classification Technical Rles (Rules & Guidance for Classification of Ships Using Low-flashpoint Fuels)

- Notice for Establishment to the KR Technical Rules(Guidance for Photovoltaic Systems Onboard Ships)

- Fire Safety of RO-RO Passenger Ships in Service

- (2025-IMO-11) LNG Bunkering Manifolds

-

- Notice for Amendments to KR Classification Technical Rules (Pt 9 Ch 2 of Rules/Ch 16 of Guidance for LFFS)

- Notice for Amendments to KR Classification Technical Rles (Rules & Guidance for Classification of Ships Using Low-flashpoint Fuels)

- Notice for Establishment to the KR Technical Rules(Guidance for Photovoltaic Systems Onboard Ships)

- Fire Safety of RO-RO Passenger Ships in Service

- (2025-IMO-11) LNG Bunkering Manifolds

AI Convergence Center

KIM Jongoh(Part Leader)

JANG Miseon(Deputy Senior Researcher)

PAIK Daeyu(Researcher)

1. AI trend in fields of design

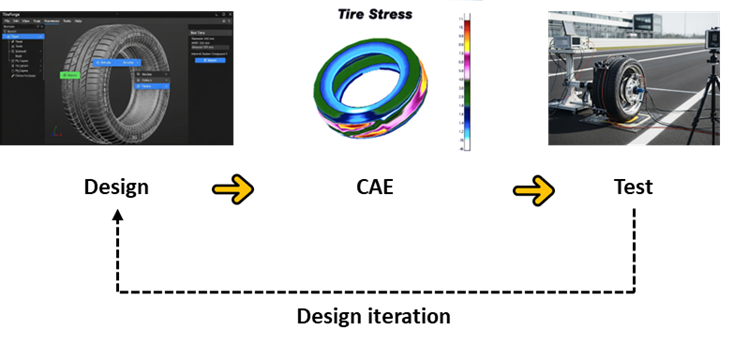

Traditionally, the designer, as shown in 'Figure 1,' carries out design to meet specific requirements using CAD (Computer-Aided Design) programs. This is followed by a simulation using CAE (Computer-Aided Engineering) programs to evaluate whether the product meets those requirements and performance. Once sufficient performance is verified through the CAE process, a prototype is created and tested. This iterative process is repeated to improve product performance and reduce manufacturing costs.

When a design is complex and involves various physical laws, designers often find it difficult to determine the numerous design variables required to meet all requirements. Rather than designing with a clear direction, they tend to rely on own experience or perform repetitive tasks. CAE work based on finite element analysis including modeling and analysis is a very time-consuming task and labor-intensive process that constitutes a significant part of the overall design workflow.

Figure 1. Traditional Design Process

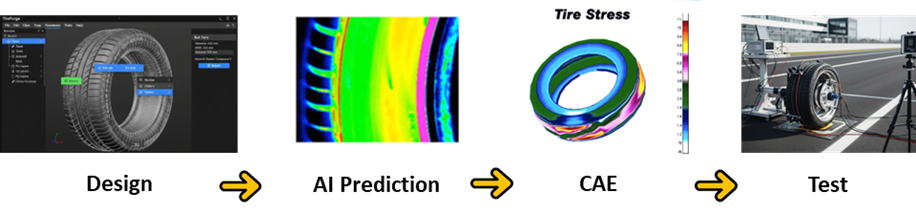

To improve the efficiency of CAE work, AI technology is being introduced into the design field. As shown in 'Figure 2', this involves using an AI prediction model that can perform simulations similar to the bottleneck-prone CAE process. By using this model, designers can check product performance in real-time as they design. This allows them to quickly meet requirements and explore various design options to achieve an optimal design.

However, since AI prediction models have inherent errors, they cannot completely replace CAE work. Therefore, a final CAE analysis is still performed to verify the reliability of the AI model's results.

Figure 2. AI Prediction Model-Based Design Process

KR would like to share our experience applying AI-CAE to the design of ship hull structural members and present the use cases of AI prediction models.

2. Development AI Prediction Model for Hull Brackets

A ship's hull is a complex structure composed of many plates and stiffeners. At locations where multiple plates meet, various and complex stresses (internal force per unit area to resist external forces) occur. The IACS Common Structural Rules mandate micro-element modeling followed by stress and fatigue analysis at these intersection points to ensure safety, as shown in 'Figure 3'. These locations are structurally complex, have diverse shapes, and are numerous, requiring significant time from designers.

To ensure structural safety, bracket members are often installed at these complex intersections. The stress on these brackets is highly variable and difficult to predict. Consequently, designers must perform repetitive micro-element modeling and analysis to determine the appropriate bracket shape and dimensions, which acts as a major bottleneck in the overall design process.

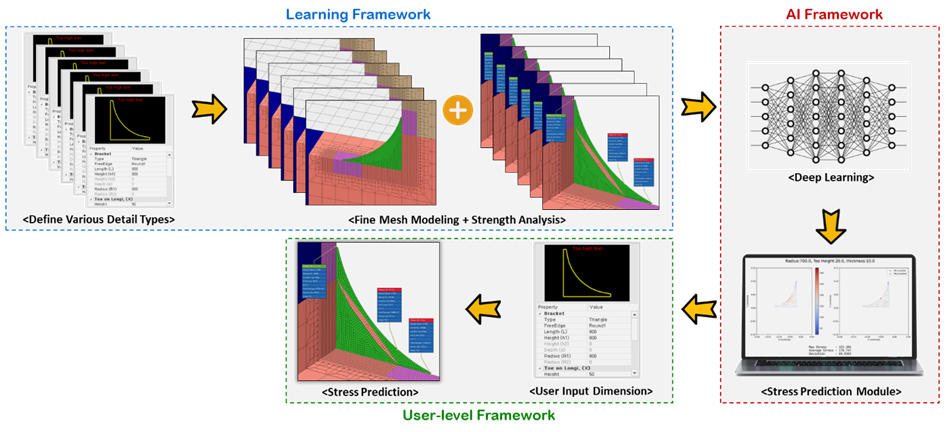

KR has developed an AI prediction model for stress values based on bracket design variables (bracket radius, bracket thickness, and toe height). This model was integrated into KR's flagship software, SeaTrust-HullScan, to explore the potential of AI-CAE. The framework for the AI prediction model, as shown in 'Figure 3', consists of learning data generation, model training, and model utilization.

Figure 3. AI Prediction Model Framework

Securing sufficient learning data is crucial for creating a reliable model. Since AI-CAE learning data consists of finite element modeling and structural analysis data, manual data generation is very time-consuming and inefficient. To overcome this, KR automated the finite element modeling and structural analysis task for the range of design variables used in bracket design. KR selected an appropriate neural network model to represent stress in the finite element bracket model and proceeded with training the AI prediction model. The resulting model can be used in a user environment for various purposes to enhance design productivity.

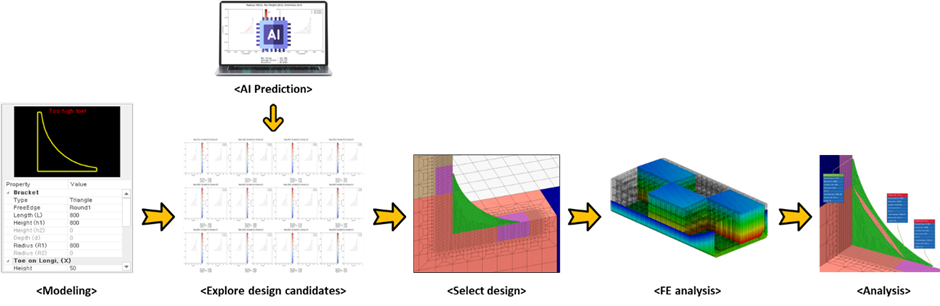

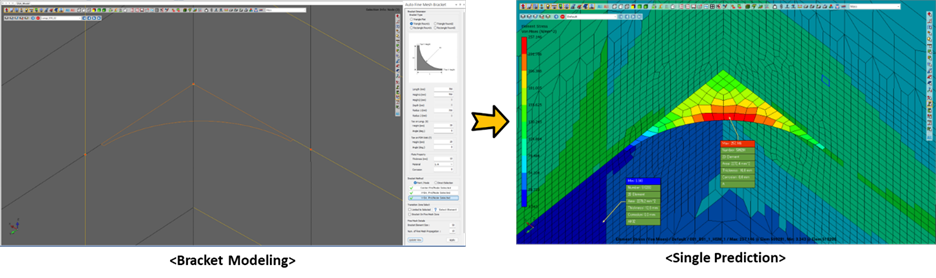

In traditional design, a designer would input the bracket shape and dimensions to generate a finite element model, perform a structural analysis, and then evaluate the results. With the AI prediction model, however, these complex modeling and analysis steps can be replaced. As soon as the designer inputs the bracket's shape and dimensions, the AI model instantly displays stress and its location on the bracket. This allows for real-time evaluation of the current design and simultaneous review of multiple design candidates. The designer can then choose the optimal design from the reviewed options and perform a structural analysis to verify the reliability of the AI prediction model. This approach drastically reduces design time and innovates the complex process by replacing the modeling and analysis steps that were previously bottlenecks. It accelerates decision-making by enabling quick evaluation of diverse designs.

Figure 4. AI Prediction Model-Based Bracket Design Process

3. Application of AI Prediction Model

The bracket stress AI prediction model can be used in various ways within SeaTrust-HullScan. Instead of the traditional process of structural analysis of "upload to server > analyze > download results," a designer can now input the bracket shape and dimensions and instantly see the stress and its location as the model is being created ('Figure 5'). The AI model also allows for simultaneous evaluation of various design candidates and efficient review by sorting results based on key design parameters.

Figure 5. Real-time Modeling and Stress Prediction

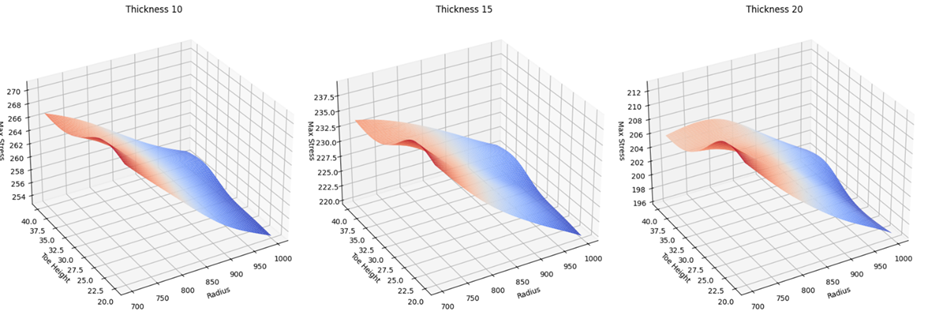

The AI prediction model-based response surface of for ‘Design Variable’-‘Maximum Stress’ as a function of is shown as a 3D graph based on thickness ('Figure 6', ‘Design Variable’-‘Maximum Stress’ Response Surface - X-axis: Toe Height, Y-axis: Radius, Z-axis: Max Stress). The graph shows similar surface shapes for different thicknesses, indicating that both bracket radius and toe height influence the maximum stress, but the bracket radius has a more significant effect. The change in maximum stress appears non-linear in the regions with low bracket radius and toe height. If designing within this non-linear range, it can be very time-consuming due to the difficulty in predicting the design outcome.

Figure 6. ‘Design Variable’-‘Maximum Stress’ Response Surface

Thus, using an AI prediction model allows not only for a quick review of design outcomes but also for an understanding of the influence and sensitivity of design variables, providing an intuitive sense of the design range needed to meet requirements at initial design step.

4. Conclusion

KR have introduced the bracket stress AI prediction model and its applications. The developed AI model can be integrated with various CAD and CAE applications, making the traditionally expert-driven CAE work easier and faster. This enables rapid exploration of diverse design options, providing an opportunity to surpass conventional optimal solutions. Furthermore, designers can shift their focus from labor-intensive CAE tasks to higher-level work, such as evaluating and finding better designs.

KR is actively developing AI-CAE technologies that can be applied to various user applications and looks forward to collaborating with clients to innovate the design process.