Writers

KANG Soomin Deputy Senior Surveyor, KWON Jinwoo Deputy Senior Surveyor

LEE Iksung Senior Surveyor, IM Dongguk Senior Surveyor

Alternative Fuel Technology Research Team

■ Background

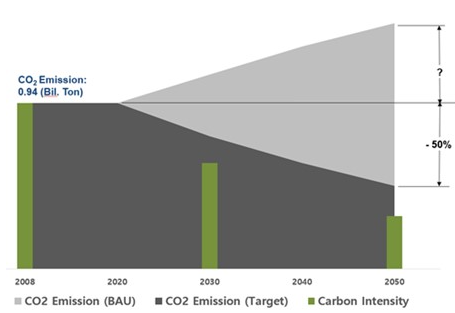

The International Maritime Organization (IMO) has set a target to reduce carbon emissions by 40% based on 2008 levels by 2030 and 70% by 2050. In addition, the shipping industry must reduce its greenhouse gas emissions by 50% by 2050. To achieve these strategic goals, the Energy Efficiency Design Index (EEDI) is applied to new ships, with a mandatory requirement to improve efficiency by 30% compared to the baseline from 2025 onwards. For existing ships that are not subject to the EEDI, the Existing Ship Energy Efficiency Index (EEXI) will be applied to improve efficiency to the same level as the EEDI. To meet GHG reduction targets, existing ships are being considered for engine power limitation, the application of after-treatment and energy efficiency improvement technology, and the conversion to biofuels. For new ships, the application of alternative fuels such as low-carbon and zero-carbon fuels is being considered.

Figure 1. Initial IMO strategy on reduction of GHG emissions from ships

(Source=KR Decarbonization)

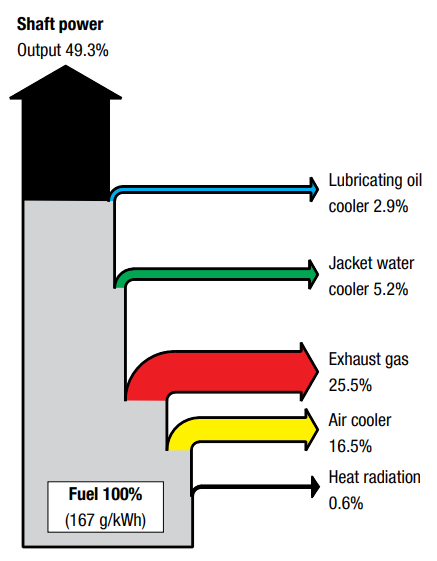

Across various technologies, several studies on the application of those that can improve energy efficiency are being carried out. One such technology in development is thermoelectric generation technology that can convert some of the thermal energy lost as waste heat in a ship`s main propulsion or generator into electrical energy through a thermoelectric module. A thermoelectric generation system generates electricity through thermoelectric modules by utilizing the temperature difference between waste heat generated in the engine and the low-temperature fluid such as cooling water. Thermoelectric generation systems can be applied to both the intake and exhaust sections of an engine, but when applied to the exhaust section, the temperature of the waste heat generated is higher than that of the intake section. Therefore, when the thermoelectric generation system is applied to the exhaust section, the thermoelectric generation system efficiency increases.

Figure 2. Engine Heat balance diagram

(Source=MAN diesel & turbo)

However, when the thermoelectric generation system is applied to the exhaust section, the particulate matter contained in the engine exhaust gas accumulates in the thermoelectric module. This results in a decrease of the power generation efficiency of the thermoelectric generation system. In response, KR conducted a 'Study on the Efficiency Characteristics of Thermoelectric Generation System’ analyzing the amount of particulate matter emissions from an engine using a diesel particulate filter, which is a particulate matter reduction system.

■ Experimental setup

In this study, the high-speed engine test bed of the Green Ship Test & Certification Center was used. The test used a 403 kW (@ 1,800 rpm) marine diesel engine and dynamometer for control engine load and revolution, and D.C Electronic Load (PEL-2040a) was used to measure the amount of power generated from the thermoelectric generation system. The operating conditions that satisfy the exhaust gas flow rate, temperature and coolant supply conditions set in the design stage of the thermoelectric generation system were selected as the test conditions. Under operating conditions, the power generation efficiency characteristics of the thermoelectric generation system were compared by operating for 10 hours each before and after the application of a diesel particulate filter.

Figure 3. Experimental setup

Exhaust mass flow rate [kg/h] | 1,446 |

Exhaust gas temperature [℃] | 223 |

Cooling water volume flow rate [m3/h] | 8 |

Cooling water temperature [℃] | 28 |

■ Experimental results and analysis

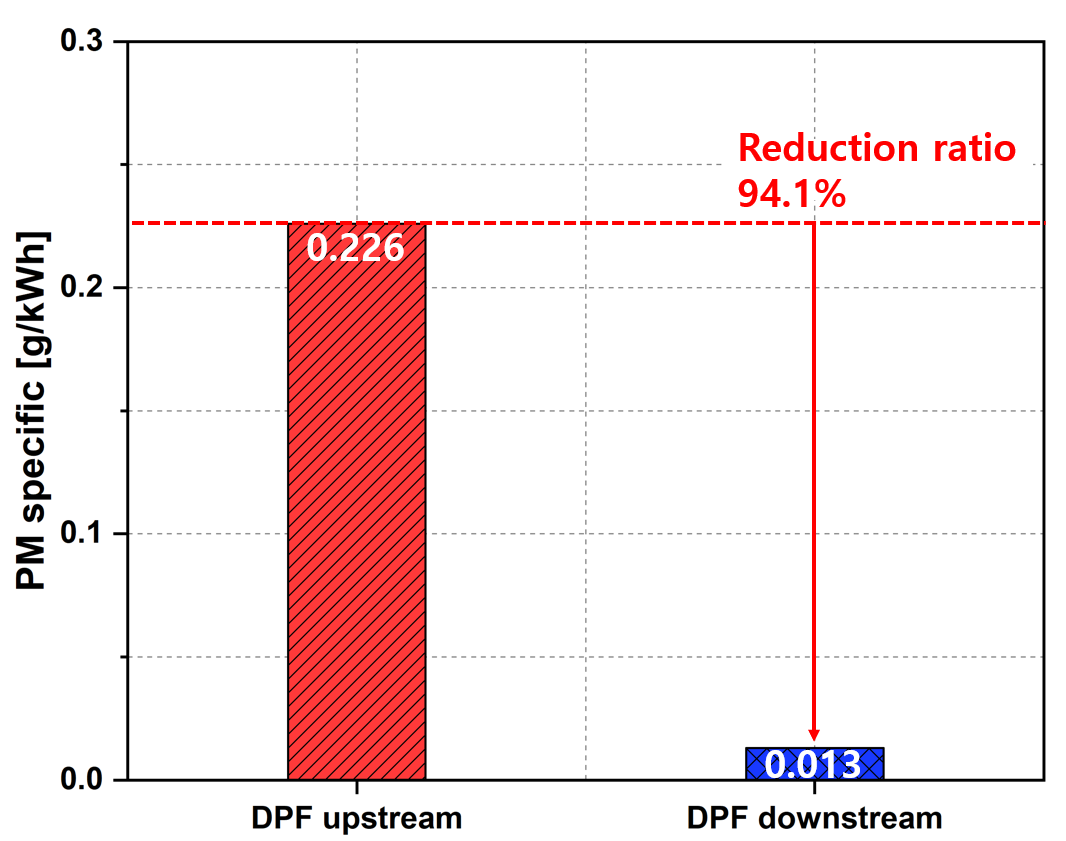

As a preliminary study to confirm the reduction characteristics of particulate matter, the particulate matter emissions from before and after the application of a diesel particulate filter were compared. A particulate matter sampling device (SPC-478) that collects particulate matter in a sample filter and then measures the particulate emission factor was used. As a result of measurement under operating conditions, the particulate emission factor before application of a diesel particulate filter was 0.226 g/kWh. After the application, the particulate emission factor was 0.013 g/kWh. The diesel particulate filter showed a reduction performance of 94.1%.

Figure 4. Diesel particulte filter reduction performance

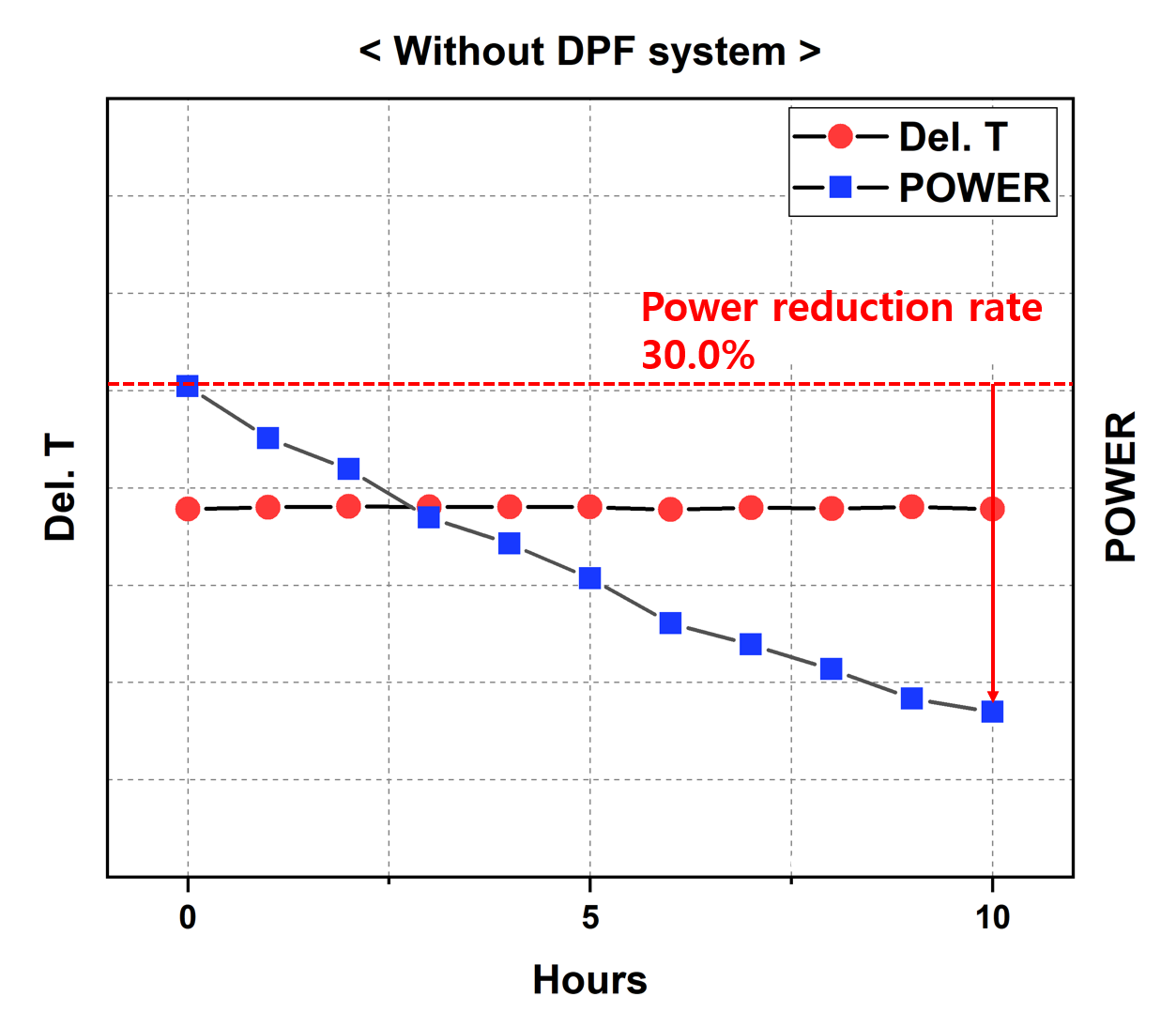

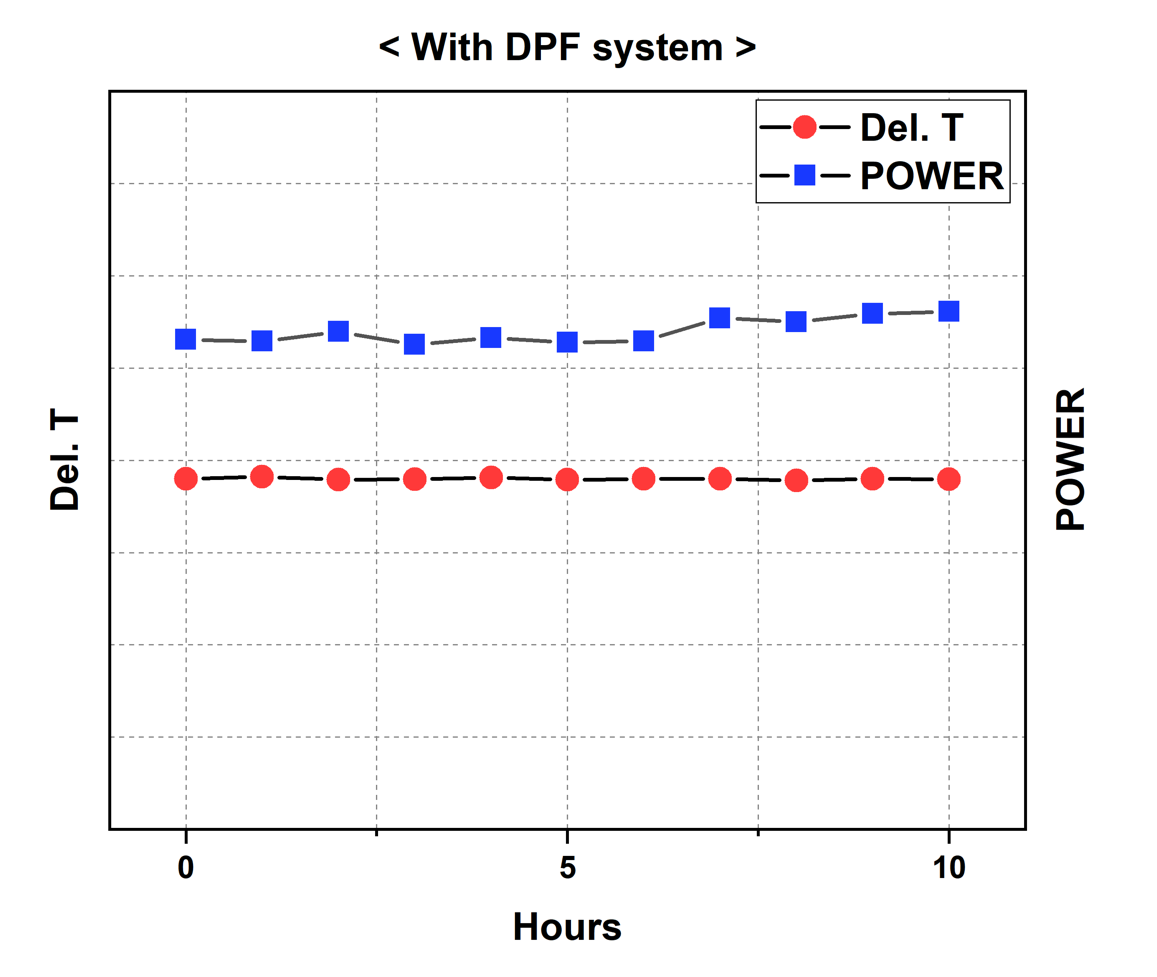

Subsequently, the power generation efficiency characteristics of the thermoelectric generation system were compared by maintaining operations for 10 hours, each before and after the application of a diesel particulate filter under operating conditions. It was confirmed that as the operating time accumulated, the power generated by the thermoelectric generation system decreased without the application of a diesel particulate filter. The power generated after 10 hours of operation decreased by 30% compared to the initial power generated. On the other hand, when a diesel particulate filter was applied, the amount of power generated by the thermoelectric generator was maintained during 10 hours of operation without a decrease in performance. It shows that the application of the particulate matter reduction system is necessary to keep the performance of a thermoelectric generator as a waste heat recovery system of exhaust gas.

Figure 5. Power generation efficiency characteristics of the thermoelectric generation system

■ Conclusions

Based on the results, it was confirmed that the power generation efficiency was different before and after the application of the diesel particulate filter. It was also demonstrated that the performance of the thermoelectric module was continuously maintained when particulate matter that can accumulate on the thermoelectric module is reduced through the application of the diesel particulate filter. An application of alternative fuels such as low-carbon(i.e. LNG) and zero-carbon fuels(i.e. ammonia) can reduce particulate matter emissions by more than 90% compared to conventional fuels. Accordingly, when a thermoelectric generation system is applied to a propulsion engine with alternative fuels, energy efficiency can be continuously improved. In the future, a thermoelectric generation system will be applied to engines with alternative fuels to analyze the characteristics of electricity generated according to fuel characteristics.