-

- Technological and Collaborative Achievements at KORMARINE 2025

- KR launches digital platforms PILOT and POWER to advance data-driven shipping decarbonization

- KR Participates as a Principal Sponsor in the TradeWinds Forum

- Tripartite 2025 Successfully Concluded

- KR Holds 2025 Digital Technology Seminar

- KR Grants AIP for HD Hyundai Mipo’s Hybrid Battery Operation Technology

- KR Grants AIP for HD Hyundai Mipo SOFC-Integrated Hybrid Ro-Ro Vessel

- KR Hosts Seminar with PSC Officers from Australia and New Zealand

-

- Notice for amendment of KR Technical Rules (Rules and Guidance for the Classification of Steel Ships & Other Rules and Guidance)

- Guidance on the Amendment to SEEMP Part II and III

- MEPC ES.2-News Flash

- [2025-EU-01] Guidance on EU Regulation Restricting the Use of PFAS-Containing Firefighting Foams

- Revision of ”Guidelines for Floating Offshore Wind Turbine Structure”

- [2025-IMO-15] IMSBC Code Amendments (08-25)

- Technological and Collaborative Achievements at KORMARINE 2025

- KR launches digital platforms PILOT and POWER to advance data-driven shipping decarbonization

- KR Participates as a Principal Sponsor in the TradeWinds Forum

- Tripartite 2025 Successfully Concluded

- KR Holds 2025 Digital Technology Seminar

- KR Grants AIP for HD Hyundai Mipo’s Hybrid Battery Operation Technology

- KR Grants AIP for HD Hyundai Mipo SOFC-Integrated Hybrid Ro-Ro Vessel

- KR Hosts Seminar with PSC Officers from Australia and New Zealand

- Notice for amendment of KR Technical Rules (Rules and Guidance for the Classification of Steel Ships & Other Rules and Guidance)

- Guidance on the Amendment to SEEMP Part II and III

- MEPC ES.2-News Flash

- [2025-EU-01] Guidance on EU Regulation Restricting the Use of PFAS-Containing Firefighting Foams

- Revision of ”Guidelines for Floating Offshore Wind Turbine Structure”

- [2025-IMO-15] IMSBC Code Amendments (08-25)

-

- Technological and Collaborative Achievements at KORMARINE 2025

- KR launches digital platforms PILOT and POWER to advance data-driven shipping decarbonization

- KR Participates as a Principal Sponsor in the TradeWinds Forum

- Tripartite 2025 Successfully Concluded

- KR Holds 2025 Digital Technology Seminar

- KR Grants AIP for HD Hyundai Mipo’s Hybrid Battery Operation Technology

- KR Grants AIP for HD Hyundai Mipo SOFC-Integrated Hybrid Ro-Ro Vessel

- KR Hosts Seminar with PSC Officers from Australia and New Zealand

-

- Notice for amendment of KR Technical Rules (Rules and Guidance for the Classification of Steel Ships & Other Rules and Guidance)

- Guidance on the Amendment to SEEMP Part II and III

- MEPC ES.2-News Flash

- [2025-EU-01] Guidance on EU Regulation Restricting the Use of PFAS-Containing Firefighting Foams

- Revision of ”Guidelines for Floating Offshore Wind Turbine Structure”

- [2025-IMO-15] IMSBC Code Amendments (08-25)

PARK Kido, Senior Surveyor

Alternative Fuel Technology Research Team

Electric propulsion system

Electric propulsion ships generate electrical energy from a power source and utilize it to power the propulsion system and onboard power supply through power converters and electric motors. Electric-powered ships in operation around the world are powered by diesel generators, but in recent years, due to the issue of emissions from ships, environmentally friendly energy sources such as batteries and fuel cells are being used, and ships are being equipped and operated in a hybrid manner that applies multiple power sources such as internal combustion engine generators, fuel cells, and batteries.

Compared to diesel engine-based ships, electric-powered ships can utilize eco-friendly energy sources such as batteries and fuel cells, which can reduce fuel consumption and emissions, and provide a comfortable environment for passengers with less noise and vibration, making them an important technology to meet international environmental regulations and sustainable maritime transportation needs.

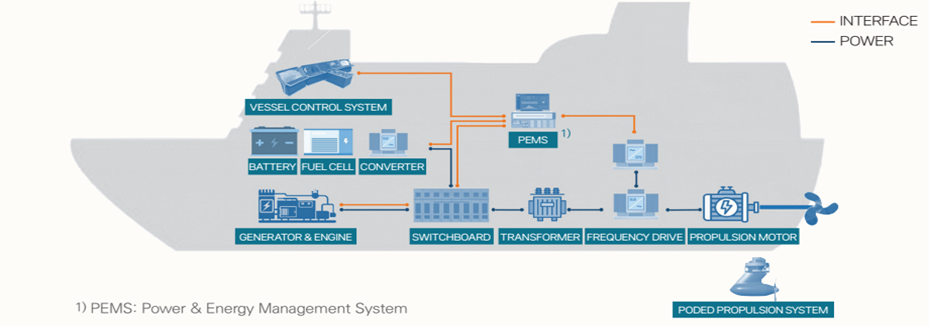

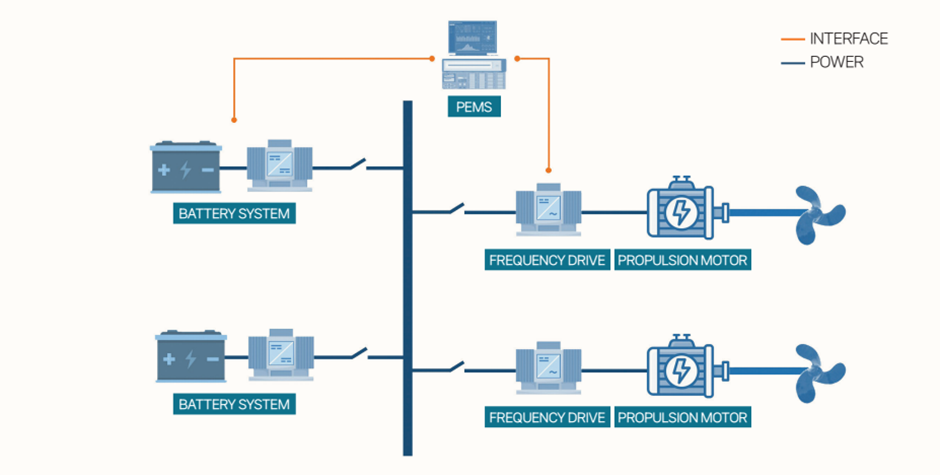

Figure 1. Schematic diagram of the electric propulsion system

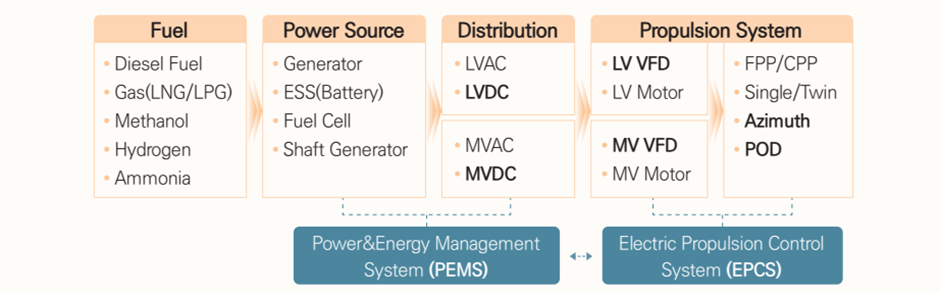

Figure 2. Block diagram of electric system

Electric-powered ships are characterized by decarbonization, efficiency, and automation. Electric-powered ships can reduce greenhouse gas emissions through flexible configuration of energy sources such as engines using fuels like LNG, hydrogen, and ammonia, as well as battery systems (ESS) and fuel cells.

For ships that can optimize power generation sources by load and have large load fluctuations, electric motors are more efficient at low loads than engines, so they are more energy efficient than direct engine propulsion.

Electric propulsion systems have been proposed as a way to reduce air pollutants and greenhouse gases generated by ships because they can use various power generation sources such as batteries and fuel cells, and have additional advantages such as excellent braking ability and high adjustability of propulsion motor speed/torque. In large ships, the electric propulsion system primarily propels the vessel by using electrical energy, which is generated by driving a generator and then supplied to a propulsion motor. This system typically consists of an engine generator, a power distribution system, a power converter, and a propulsion motor.

Marine electric propulsion systems are divided into different system types depending on how the power source is configured: generator-based electric propulsion systems, hybrid (combined power source) electric propulsion systems, battery-based electric propulsion systems, and fuel cell-based electric propulsion systems. Each has its own role and characteristics, depending on the operational characteristics and purpose of the vessel.

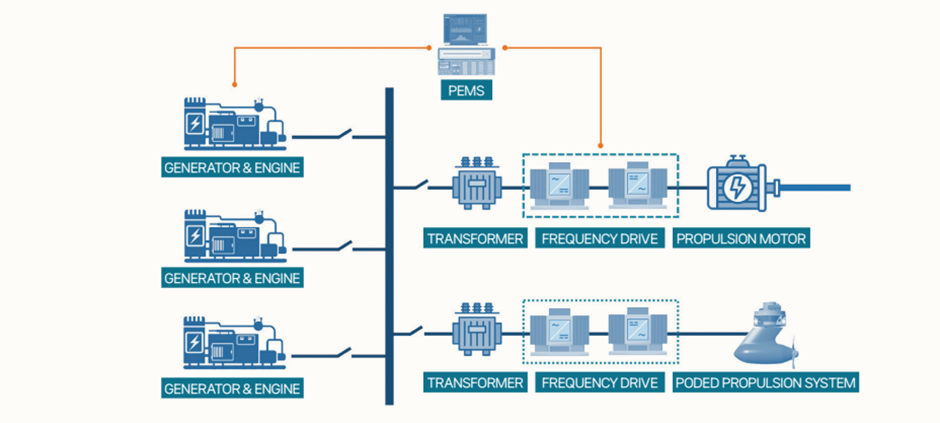

Generator-based electric propulsion

A generator-based electric propulsion system generates electricity through a generator to drive an electric motor, and is mainly used for large ships with high energy demand and relatively large load fluctuations, such as cruise ships, large container ships, and LNG carriers.

This system is efficient in energy distribution, and since the electric motor generates high efficiency (over 90%) even at low loads compared to diesel engines, it is possible to adjust the number of generators to supply only the required power according to the ship’s load, thus saving fuel.

In addition, because the electric propulsion system requires only an electric motor to be installed in the engine room and power to be supplied using electric cables, it is possible to distribute the engine equipment in consideration of the installation environment and space of the ship, and it is easy to design redundancy.

Compared to the main engine, the POD type thruster produces less noise and vibration, and it is advantageous for icebreakers and ships with dynamic positioning (DP) systems because it provides accurate propeller speed control across all operating speeds and high torque in the low speed range.

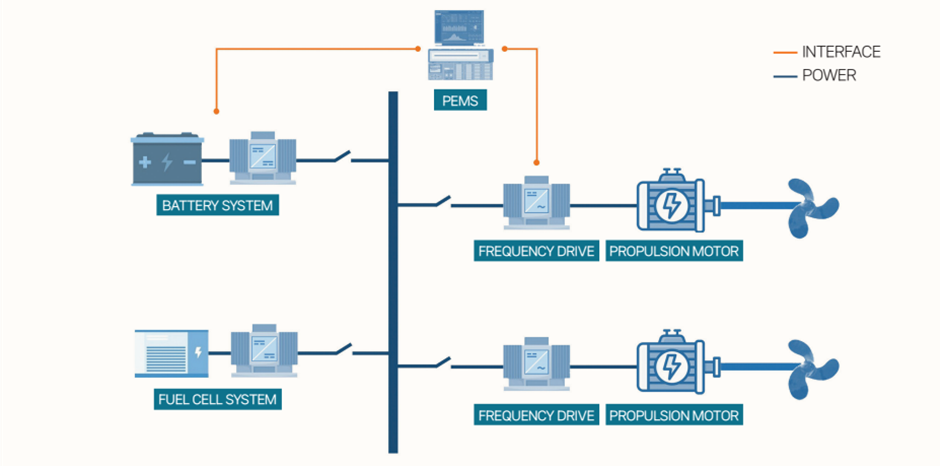

Figure 3. Block diagram of Hybrid electric propulsion system

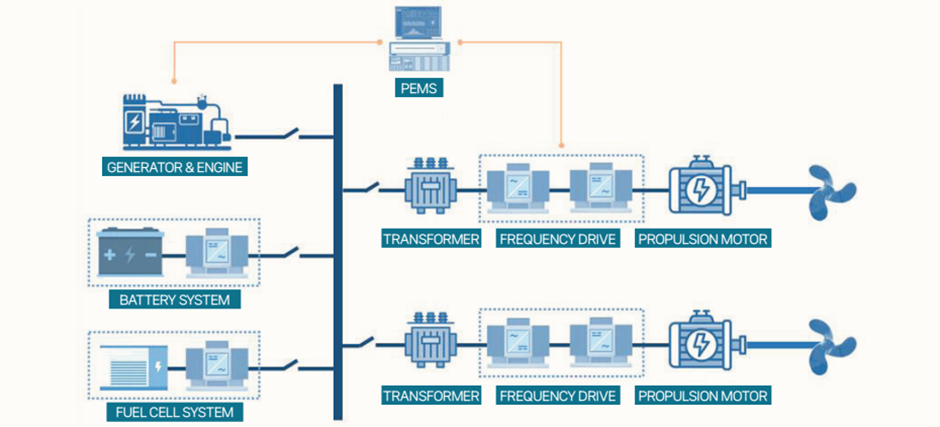

Hybrid Electric Propulsion System

The hybrid electric propulsion system is a method of supplying power by combining the engine generator and battery system in parallel with the power supply system, and is applied to various ships such as Ro-Ro ships, medium- sized passenger ships, and multi-purpose work ships. The system must be configured to supply power according to the operating status of the generator and the load characteristics of the ship, and to stably supply power to the distribution board through grid voltage and frequency control.

It is a zero-emission system that uses only batteries for low-speed operation, enabling effective ship operation in areas where engine emissions must be controlled, such as in in ECA (Emission Control Area). The power supply method can be flexibly selected according to the operation situation, such as using a generator during high-speed operation, and provides fuel savings and emission reduction effects.

Figure 4. Block diagram of Hybrid electric propulsion system

Battery-based electric propulsion system

Battery-based electric propulsion systems utilize batteries as the primary source of power and are ideal for small to medium-sized vessels on short routes, such as short-haul passenger vessels or harbor workboats.

They also have zero carbon emissions, low noise and vibration, and are ideal in areas with increased environmental regulations. However, the distance of the voyage may limit the battery capacity, and if the daily operational frequency is high, a dedicated charging system, such as fast charging, can be built to recharge the onboard battery system, which is often utilized on smaller vessels.

Electric vehicles with batteries are charged through a charging system consisting of a power converter, but ships need to be supplied with separate power because they need to use auxiliary and onboard power equipment even when at anchor. Since the battery system cannot be charged and discharged simultaneously, the power required by the ship must be supplied through the Alternative Maritime Power (AMP) and utilized as both onboard power and charging power for the battery system, and the shore power supply system must be configured in consideration of the power used.

Figure 5. Block diagram of Battery-based electric propulsion system

Fuel cell-based electric propulsion system

Unlike conventional engines that use fossil fuels, fuel cell-based electric propulsion systems convert the chemical energy of fuel into electrical energy to power the ship’s electric propulsion system, which is a system that is attracting attention as a zero-emission power generation source, similar to a battery system that can store and supply power to improve the energy efficiency of ships.

Fuel cells can also utilize a variety of fuels, including methanol, ammonia, and liquefied natural gas (LNG), in addition to hydrogen, giving them flexibility in how they are fueled, especially with next-generation green fuels such as liquid hydrogen and ammonia, which can dramatically reduce carbon emissions.

In terms of design, fuel cells can be modular, allowing for a more efficient use of space than the traditional engine room-centric structure, and in large ships, multiple fuel cells can be distributed to optimize energy management. Major countries are building ships with fuel cell systems, such as hydrogen carriers and passenger ships. However, the disadvantages include high initial investment costs and limited fuel storage and supply infrastructure.

Figure 6. Block diagram of Fuel cell-based electric propulsion system

Electric propulsion systems can be combined with green power sources to reduce greenhouse gas emissions to a certain extent, depending on the system configuration, or can be adapted to become a completely green ship with zero emissions. However, electric propulsion technology is not universally suitable for all ship types.

The efficiency of the system depends on the vessel’s operation and load profile, so the operating conditions of the vessel must be carefully analyzed in the early stages of design and the propulsion system selected accordingly. For example, for vessels that operate at constant power, such as large cargo ships, an electric propulsion system may be less energy efficient than a direct engine drive due to losses in the energy conversion process.

On the other hand, the advantages of electric propulsion are maximized for offshore vessels, tugboats, and special purpose vessels that are subject to frequent arrivals and departures and large load fluctuations.

While major countries are already embracing the concept of synchronizing electric propulsion vessels, Korea remains in the R&D and demonstration hub phase. Due to its market structure, which focuses on overseas, packaged systems, Korea faces a number of shortcomings. To overcome these limitations, Korea must modularize and integrate technologies, ensure system block operability, build off board power supply hardware, and strengthen demonstration projects at public research institute hubs.

To overcome these limitations and strengthen technological competitiveness, the government is promoting the ‘Korean Green Ship Project’ and the ‘Electric Propulsion Ship Demonstration Project’, and is facilitating companies’ market entry through various policy incentives and technology development support programs.

In addition, to strengthen the certification base for verifying the reliability and performance of electric propulsion systems, the Korean Register of Shipping (KR) is preparing a certification system that reflects the latest technical standards, and is working with companies from the ship design stage to streamline technical review and certification procedures.

In order to secure the competitiveness of the domestic electric propulsion ship industry in the future, it is necessary to establish a technology application strategy that reflects the operating environment of ships, secure battery stability, standardize charging infrastructure, increase the localization rate of core components, and foster specialized manpower.

In addition, a technology ecosystem should be established based on an organic cooperation system between industry, academia, research, and government, and strategic technology development and demonstration projects aimed at the global market should be carried out in parallel.

These efforts will go beyond short-term responses to environmental regulations and become the basis for leading a paradigm shift in the entire shipping and shipbuilding industry and enhancing national competitiveness.