KIM Seonjin, PARK Dongwook, LEE Sangick

System Safety Research Team

1. Introduction

In support of the IMO's 2050 Net-Zero goal, KR has proposed a methodology for establishing safety zones during hydrogen bunkering — a critical process for hydrogen-powered ships regarded as next-generation zero-carbon vessels. By comparing the risk profiles of hydrogen and LNG, this methodology aims to provide practical guidance, contributing to the development of a robust safety culture for hydrogen bunkering operations.

2. Fuel Characteristics

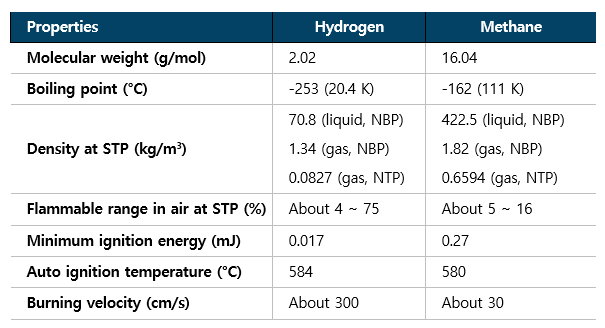

The table below provides a comparison of the properties of hydrogen and methane (the primary component of LNG), both of which are considered in this study. Hydrogen’s unique characteristics, including its low density and high diffusivity, result in a wide flammability range and low Minimum Ignition Energy (MIE), classifying it as a highly flammable gas prone to fires and explosions. Furthermore, hydrogen’s fast-burning velocity and rapid flame propagation speed significantly increase the risks compared to conventional hydrocarbons in case of fire or explosion incidents.

Based on these properties, hydrogen presents higher risk factors compared to LNG in bunkering operations.

3. Safety Zone Setting Methodology

A “safety zone” refers to a designated 3D space where flammable gas clouds may form due to potential fuel leaks. This zone restricts access and activities to minimize risks to personnel and infrastructure, primarily aiming to control leakage and ignition sources. The configuration of the safety zone is determined by various factors, including the design of the fuel transfer system, the location of the manifold on the receiving vessel, the quantity of fuel in the pipeline, and operational parameters such as flow rate, pressure, bunkering position. Environmental conditions like ambient temperature, wind speed, and direction, as well as the availability of safety equipment and the specific location of potential leaks, also play a critical role in defining the safety zone.

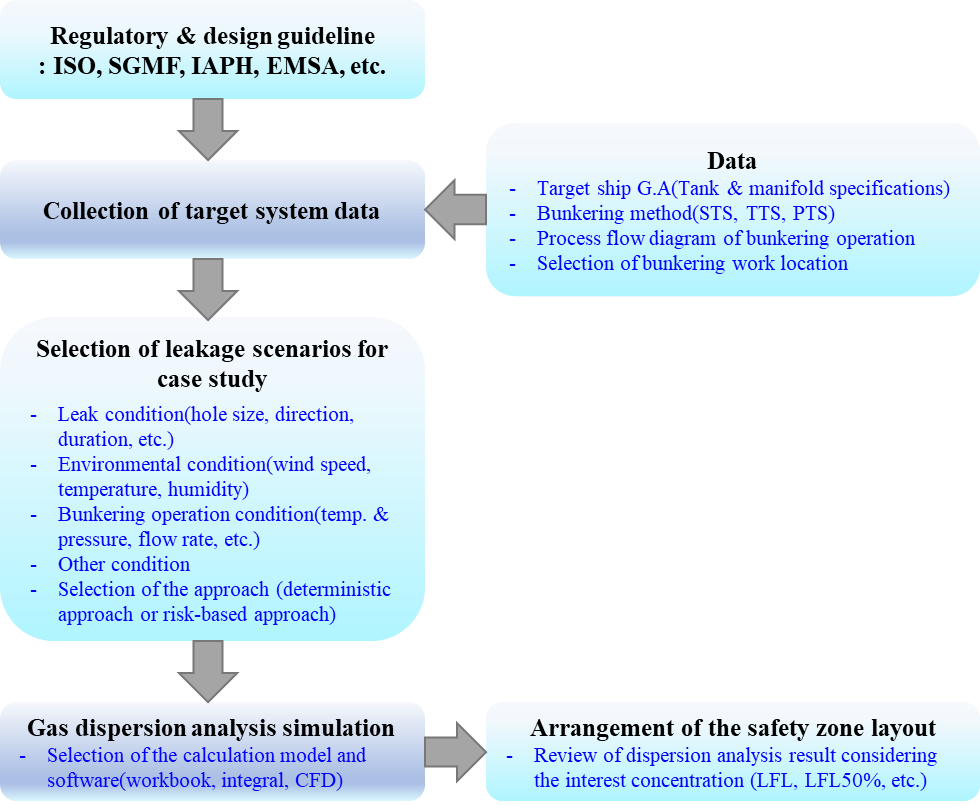

The proposed methodology for determining safety zones for alternative fuels, involves the following steps:

1) Review of Relevant Regulations and Standards

Due to the absence of hydrogen-specific bunkering regulations, LNG bunkering standards should also be referenced to ensure compliance with regulatory and contractual requirements.

2) Data Collection

This step involves gathering essential information, including:

- Details of bunkering workspace

- Specifications of receiving vessels

- Bunkering methods and processes

The study evaluates fuel transfer scenarios for compressed hydrogen, liquid hydrogen, and LNG, with supply pressure identified as a key variable.

3) Leakage Scenario Selection

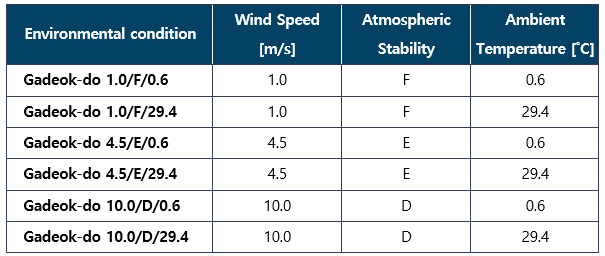

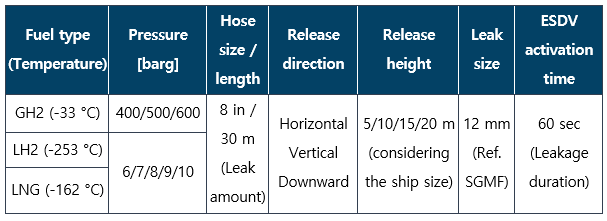

A deterministic approach, in line with ISO guidelines, was used for scenario analysis. The Port of Busan New Port was chosen as the case study site, based on the "Hydrogen Technology Development Roadmap,". Environmental conditions were derived from the Korean Meteorological Administration's climate data. To establish conservative safety zone boundaries, it was assumed that leaks occur at both ends of the supply pipe. The leakage scenarios are summarized as follows:

[Environmental condition]

[Leakage scenarios considering various bunkering conditions]

4) Gas Dispersion Analysis

Gas dispersion modeling is essential for assessing and ensuring safety by understanding the risks of flammable gas leaks leading to fires or explosions. For this study, the Integral model was employed to analyze and compare the diffusion characteristics of high-pressure hydrogen, liquid hydrogen, and LNG under various bunkering conditions. The Lower Flammable Limit (LFL) was used as the basis criteria for dispersion analysis.

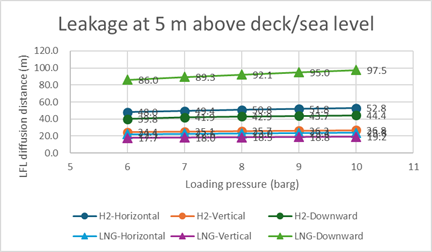

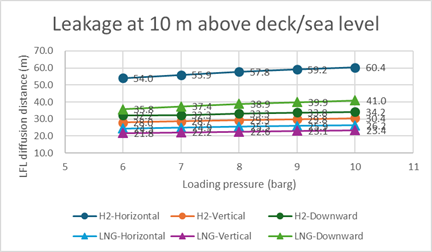

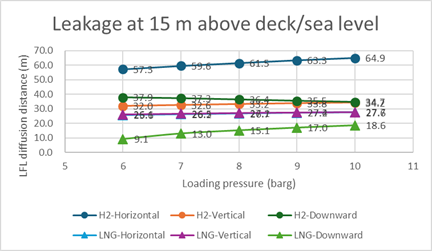

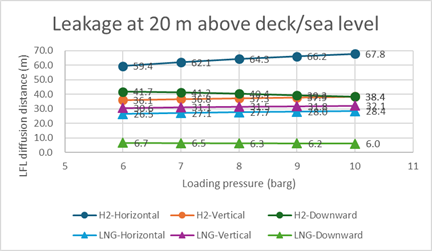

[Gas dispersion analysis result - comparison of LH2 with LNG]

Key Findings:

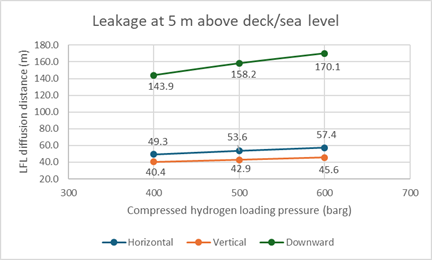

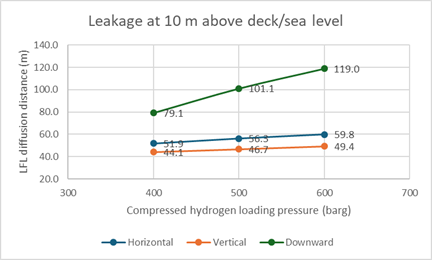

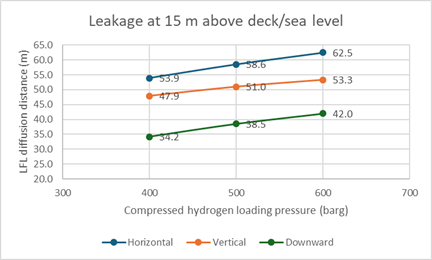

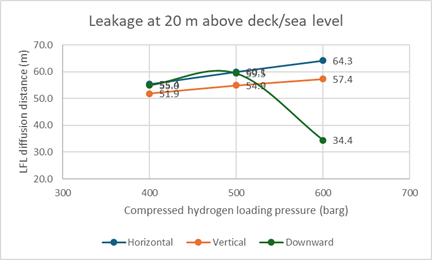

(1) Compressed hydrogen exhibits broader diffusion at higher pressures and closer proximity to deck/seawater because of jet impingement and horizontal dispersion, known as the wall jet effect of gas diffusion.

(2) Liquid hydrogen demonstrates approximately 1.9 times larger dispersion range compared to LNG under equivalent conditions.

5) Safety Zone Layout

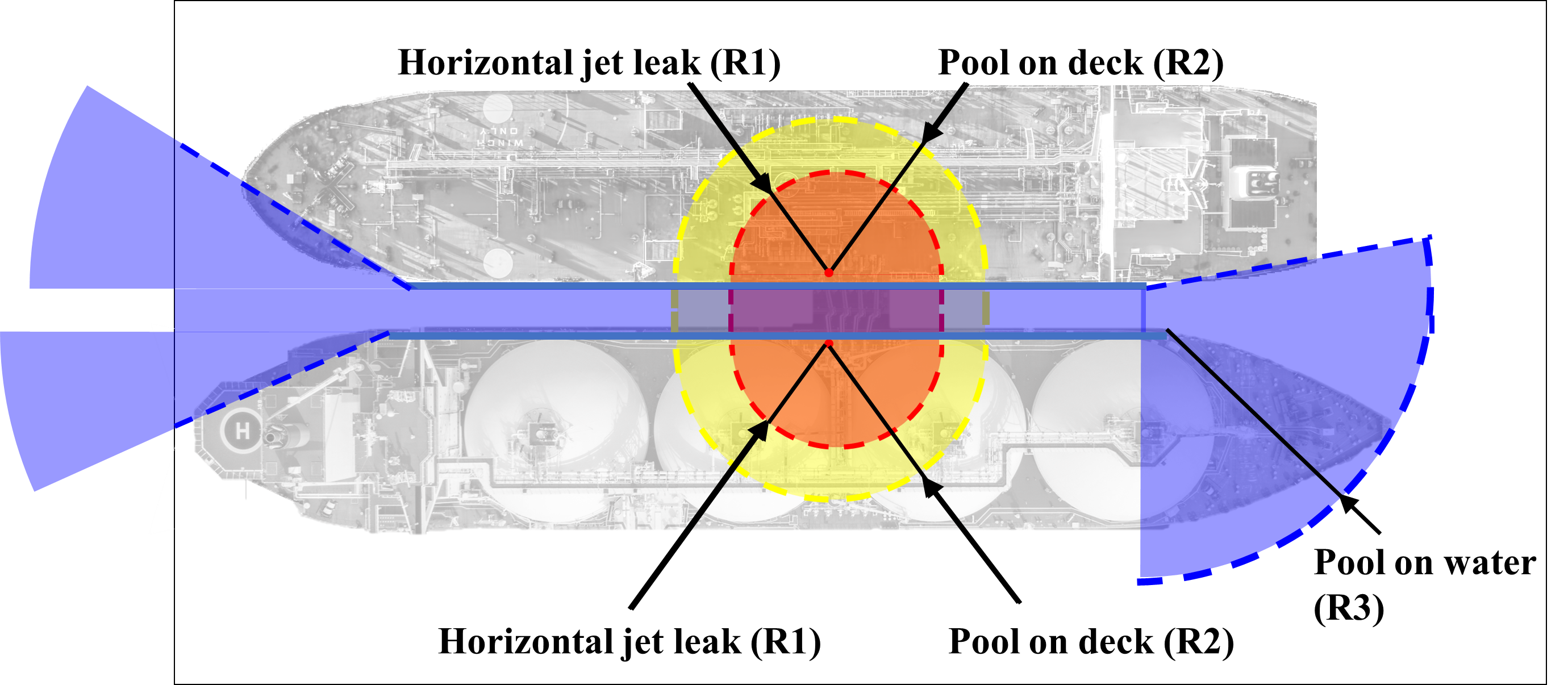

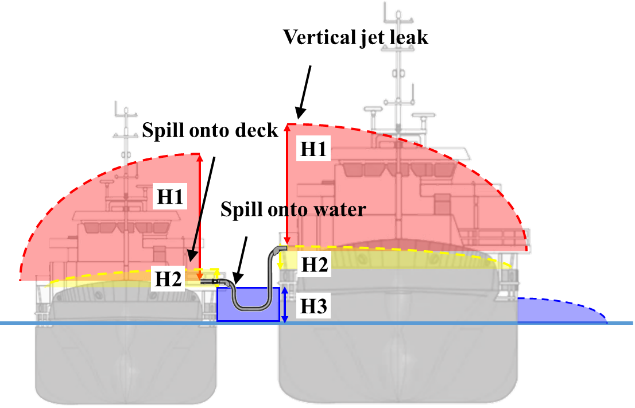

The results of the dispersion analysis are applied to the vessel layout to define safety zones, factoring in gas concentrations and other operational parameters. These safety zones are categorized into designations such as R1, R2, R3, and H1, H2, H3, as illustrated in the study, and must carry out the pre-operational evaluation.

[Graphical presentation of safety zone]

- Horizontal release (Radius, R1) & Vertical release (Height, H1))

- Pool on deck(R2) & Spill onto deck(H2)

- Pool on water(R3) & Spill onto water(H3)