System Safety Research Team

Currently, LNG is recognized as a clean alternative fuel available to the maritime industry since it can effectively fulfill the environmental requirements of international regulations proposed by the International Maritime Organization (IMO). With potential economic advantages of LNG as a fuel of ships, eco-friendly shipbuilding related to LNG is getting more attention.Various challenges to the development of LNG fuel systems and LNG bunkering vessels are being actively tried. Accordingly, orders to build LNG-fueled ships are gradually increasing. It is also expected that LNG-fueled vessels will occupy the majority of new ships around the world in the future.

(According to Clarkson research [2022.3], 290 LNG-fueled ships are currently in operating excluding LNG carriers, and as of March 2022, 15% of total ship orders (No.) and 33% of gross tonnage (GT) are construction is in progress as a LNG fuel-propelled vessel.)

"Bunkering" is the supply of solid, liquid, gaseous fuel or other energy sources as propulsion and specific-purpose energy for marine (sea) ships from a dock or dedicated ship. LNG bunkering is an operation that transports (supplies) LNG for fuel to sources such as tank-lorry, onshore pipelines and ships to receiving vessels (LNG-fueled vessels).

For the commercial introduction and spread of LNG-fueled ships, it is essential to secure LNG-fueled ship bunkering infrastructure and safe operation technology. In order to revitalize the LNG bunkering industry, the KR provides ship-to-ship (STS) LNG bunkering safety procedures and risk analysis services to perform safe and efficient LNG bunkering operations.

‘Simultaneous operations with LNG Bunkering (SIMOPS)’ is the act of simultaneously performing LNG bunkering operations and port loading/unloading operations.

SIMOPS includes cargo loading/unloading, dangerous goods loading/unloading and loading/unloading of all other kinds of cargo (stores and equipment parts for maintenance etc.). It also includes the movement towards cargo on board ships that may affect or impede bunkering operations, such as embarkation/disembarkation of passengers, handling of flammable chemicals and other low flash point products, supply with fuels other than LNG and other activities, such as helicopter operations etc.

Major ports such as Helsinki (2019.9), Amsterdam (2019.12), Singapore (2021.3) and Shanghai (2022.3) allow LNG bunkering SIMOPS to strengthen port competitiveness by attracting LNG-fueled vessels. If the simultaneous LNG bunkering operation cannot be performed in the port, cargo unloading and LNG bunkering operations must be performed separately, which increases the vessel's call time, which increases the cost of staying in the port and increases the operating time of the fleet.

(The prohibition against SIMOPS has a negative impact on the business activities of ships because it increases the operation time for loading/unloading and bunkering at the port. Therefore, it is necessary for the vessel to be able to perform simultaneous LNG bunkering in the port. And it must be possible to safely carry out other tasks that are performed concurrently with the ship’s unloading work)

LNG bunkering SIMOPS is a pre-confirmation of the suitability of ship-to-ship or ship-to-shore operations such as ship-to-ship risk assessment, mooring adequacy, and marine fender adequacy. This serves as a 'compatibility study' review to require a lot of manpower and resources. (e.g., review of safety standards and establishment of safety management zones for each port, etc.)

Simultaneous LNG bunkering operations can be divided into planned and unplanned SIMOPS. The difference between planned and unplanned SIMOPS is the amount of time the person in charge is aware of a particular task (before or in the process of LNG bunkering). Planned SIMOPS operations can be evaluated and prepared for risk (or SIMOPS Study) prior to vessel arrival, but unplanned events, i.e., events that occur during LNG transport, require cessation of LNG transports after risk analysis until further mitigation measures are taken. In particular, SIMOPS operations of high severity deserve special attention.

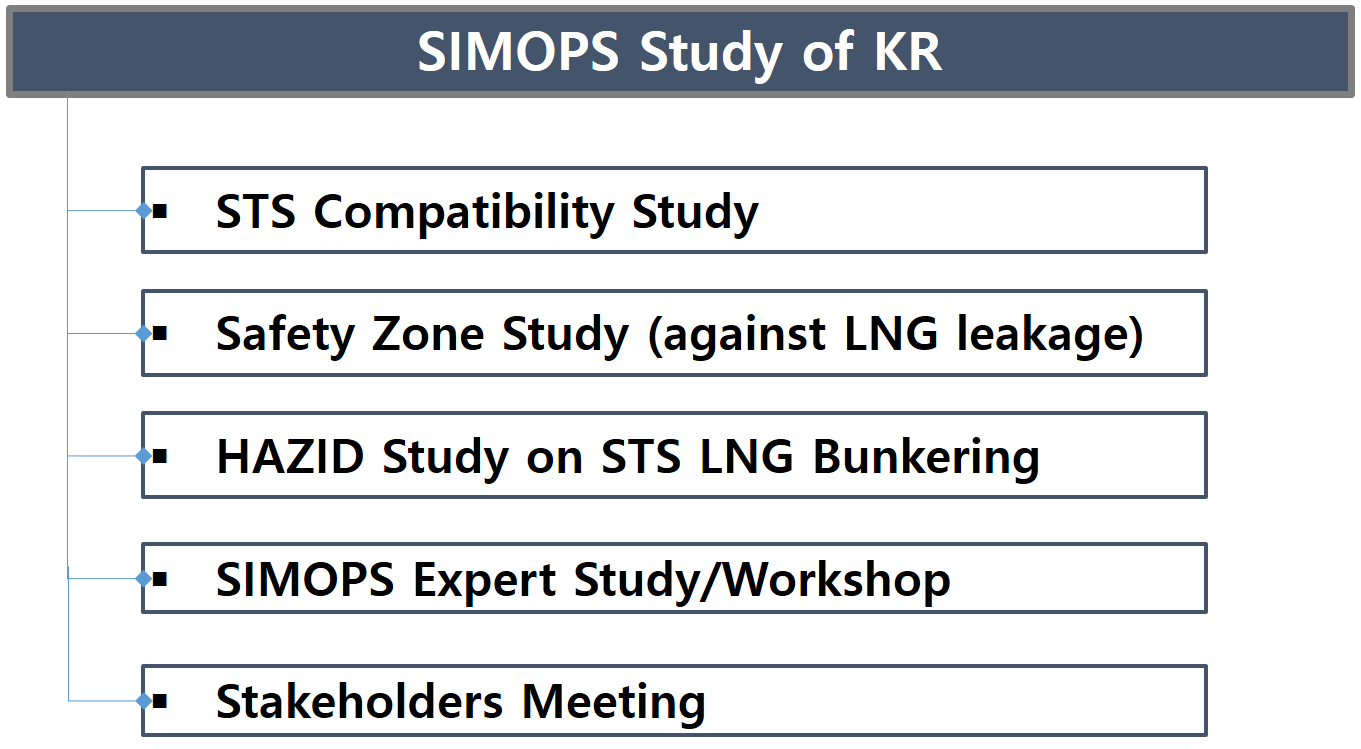

Figure 1. KR’s LNG Bunkering SIMOPS Procedure

Figure 1 shows the procedure for performing simultaneous LNG bunkering operations. To ensure smooth LNG bunkering between LNG bunkering vessels and fuel-powered vessels, a compatibility study must be completed, and risk assessments for events that may occur to bunkering are required.

After a pre-meeting and expert workshop with stakeholders on the SIMOPS is carried out, and through follow-up measures, when the risk factors identified through the expert workshop are found to be at an acceptable level, the SIMOPS of LNG bunkering is carried out.

Table 1. Ship to ship LNG Bunkering SIMOPS

|

STS LNG BUNKERING |

Simultaneous operation. (SIMOPS) | ||

|

Scope (Area) |

Only bunkering vessels and receiving vessels LNG transfer areas are considered. |

Extensive three-dimensional space for bunkering and unloading/repair work performed in the port. | |

|

(Existing STS

bunkering work only performs limited operation and risk analysis around the

bunkering vessel.) |

(SIMOPS of LNG bunkering requires securing safety throughout the entire port or the scope of operations performed simultaneously with LNG bunkering.) |

||

|

Necessary skills |

Necessary skills

and standards for the safety of bunkering vessels and receiving vessels. |

In addition to the existing STS LNG bunkering, risk assessment and safety standards for the ports (terminals) where LNG bunkering is performed are required. (In particular, there are different risk assessments and safety standards for each port.) |

|

|

Applied technology |

➊ STS risk assessment; ➌Operation manual; |

In addition to the

existing STS LNG bunkering technology, in addition to |

|

- Authorization should be granted to suspend LNG transfer operations when the risk increases significantly during concurrent operations or when the possibility is judged imminent.

- Ensure clear and effective communication with all parties.

- Management (prevention and reduction) of all risks occurring during SIMOPS work.

- It is necessary to manage the entry and exit of authorized personnel (training, equipment necessary to perform roles) within the safety management area.

The KR confirmed the necessity of simultaneous operation of LNG bunkering, and is working with organizations such as the Ministry of Oceans and Fisheries, Busan Port Authority, Korea Gas Corporation, Korea LNG Bunkering, H Line and Hyundai Steel to establish SIMOPS verification, procedures and related systems.