-

- KR Marks 65th Anniversary with Industry Forum Calling for a Korean Maritime Cluster

- KR Expands Technical Collaboration at Nor-Shipping 2025

- KR Releases 10th Issue of KR Decarbonization Magazine

- KR and HD Hyundai Samho Join Forces to Bring AI into Ship Design

- KR Teams Up with Leading Shipbuilders and KTR to Develop International Standards for Ammonia Effluent Discharge

- KR-Team Korea Holds First Wing Sail Demonstration to Advance Green Shipping

- KR and HD Hyundai Pioneer BOG Reuse System for LNG-Fueled Vessel at Berth

- KR Grants AIP to HD HHI for Innovative CHS of Membrane Ammonia Tank

- KR Chairs 54th TSCF Meeting Reinforcing Global Collaboration on Tanker Safety

-

- MEPC 83 - News Final

- MSC110 - News Flash

- Revision of " Guidelines for Ships carrying Liquefied Hydrogen in Bulk"

- Establishment of the “Guidelines for Approval of Metallic Materials in Hydrogen Service”

- [2025-IMO-08] FAQ on IMO GHG Reduction Measures

- Notification of LNG Bunkering Guidelines Issued by Directorate General of Shipping, India

- KR Marks 65th Anniversary with Industry Forum Calling for a Korean Maritime Cluster

- KR Expands Technical Collaboration at Nor-Shipping 2025

- KR Releases 10th Issue of KR Decarbonization Magazine

- KR and HD Hyundai Samho Join Forces to Bring AI into Ship Design

- KR Teams Up with Leading Shipbuilders and KTR to Develop International Standards for Ammonia Effluent Discharge

- KR-Team Korea Holds First Wing Sail Demonstration to Advance Green Shipping

- KR and HD Hyundai Pioneer BOG Reuse System for LNG-Fueled Vessel at Berth

- KR Grants AIP to HD HHI for Innovative CHS of Membrane Ammonia Tank

- KR Chairs 54th TSCF Meeting Reinforcing Global Collaboration on Tanker Safety

- MEPC 83 - News Final

- MSC110 - News Flash

- Revision of " Guidelines for Ships carrying Liquefied Hydrogen in Bulk"

- Establishment of the “Guidelines for Approval of Metallic Materials in Hydrogen Service”

- [2025-IMO-08] FAQ on IMO GHG Reduction Measures

- Notification of LNG Bunkering Guidelines Issued by Directorate General of Shipping, India

-

- KR Marks 65th Anniversary with Industry Forum Calling for a Korean Maritime Cluster

- KR Expands Technical Collaboration at Nor-Shipping 2025

- KR Releases 10th Issue of KR Decarbonization Magazine

- KR and HD Hyundai Samho Join Forces to Bring AI into Ship Design

- KR Teams Up with Leading Shipbuilders and KTR to Develop International Standards for Ammonia Effluent Discharge

- KR-Team Korea Holds First Wing Sail Demonstration to Advance Green Shipping

- KR and HD Hyundai Pioneer BOG Reuse System for LNG-Fueled Vessel at Berth

- KR Grants AIP to HD HHI for Innovative CHS of Membrane Ammonia Tank

- KR Chairs 54th TSCF Meeting Reinforcing Global Collaboration on Tanker Safety

-

- MEPC 83 - News Final

- MSC110 - News Flash

- Revision of " Guidelines for Ships carrying Liquefied Hydrogen in Bulk"

- Establishment of the “Guidelines for Approval of Metallic Materials in Hydrogen Service”

- [2025-IMO-08] FAQ on IMO GHG Reduction Measures

- Notification of LNG Bunkering Guidelines Issued by Directorate General of Shipping, India

KIM Houngsoo & PARK Dongwook, System Safety Research Team

1. Introduction

As the international community moves toward carbon neutrality by 2050, the shipping industry faces mounting regulatory pressure, including the International Maritime Organization (IMO) zero greenhouse gas (GHG) emissions target and the European Union (EU) Fit for 55 initiative. Market-based measures as carbon taxes and emissions trading schemes (ETS) are weighing on shipping companies' profitability and increasing decarbonization costs. In response, studies-including a report by CE Delft-have outlined pathways such as low-emission fuels and operational optimization, which could reduce GHG emissions by 36-47% by 2030, at manageable costs. In this context, biofuels have emerged as one of the viable short-to mid-term options to support the maritime sector’s decarbonization effort while using existing vessel infrastructure.

As part of this effort, HMM, a leading liner operator in South Korea, conducted a trial operation using B30 (30% biofuel blend) in 2023 on the 6,400 TEU containership HMM Tacoma as part of its early efforts to explore biofuel adoption. With this innovative trial, the liner has initiated a mid-term strategy to substitute five (5) to 10 percent of its total fuel consumption with biofuels.

Following these fuel transition initiatives, Korean Register (KR) and HMM established a Joint Development Project (JDP) to conduct collaborative research on the technical feasibility verification and safety assessment, and operational suitability of applying 100% biofuel (B100) to larger container ships. As part of the JDP, demonstration operations using B100 supplied by GS Caltex were carried out on 12 24,000 TEU-class container ships to collect operational data and assess feasibility, safety, and performance.

Building on the outcomes of these demonstration operations, HMM developed a design and operational concept for the application of B100 on a 24,000 TEU-class container ship and requested KR to conduct a risk analysis. In response, KR organized a multidisciplinary Hazard Identification (HAZID) team, comprising experts in shipbuilding, offshore plant engineering, fuel systems, and related fields, to carry out a comprehensive assessment.

2. Biofuel (B100) Properties

Biofuel (B100), considered a candidate alternative fuel for the maritime sector, is produced from renewable organic resources like used cooking oil (UCO), vegetable oils, and animal fats. Its sustainability lower net carbon footprint compared to conventional fossil fuels has let to its growing recognition as a viable decarbonization option. With virtually no sulfur content, B100 also contributes to the reduction of sulfur oxide (SOx) emissions. In addition, several commercially available B100 fuels meet the International Maritime Organization (IMO) MARPOL Annex VI requirements, supporting further demonstration trials aligned with the shipping industry's decarbonization strategies.

B100 exhibits high mechanical compatibility with existing diesel engine systems and, under certain conditions, can be used without requiring engine modifications. However, it presents a few limitations that require technical considerations.

B100 has low oxidation stability, which may result in fuel degradation during long-term storage, potentially leading to clogged filters, fuel line malfunctions, and equipment failures. In addition, compared to conventional marine diesel fuels, B100 has higher viscosity and poorer cold flow properties, which may cause fuel transfer difficulties and filter clogging, especially in low-temperature environments. B100 also readily absorbs moisture, which may result in microbial growth or fuel segregation if moisture accumulates in storage tanks. To mitigate these risks, stringent maintenance procedures are required, including regular inspections of the storage systems, careful management of the return lines, and periodic fuel quality analysis.

From a mechanical perspective, B100 exhibits higher lubricity compared to conventional diesel fuels. However, additional caution is necessary during high-temperature combustion, due to the potential for deposit accumulation and carbon formation in the combustion chamber. In practice, major engine manufacturers, such as Everllence (formerly MAN Energy Solutions) and Wärtsilä, conditionally approve the use of B100 in selected engine models, subject to compliance with specified fuel properties, operating temperatures, filtration system configurations, and fuel preheating requirements.

In conclusion, B100 offers environmental benefits while maintaining compatibility with existing fuel systems. However, its use requires prior identification of operational risks associated with its physical and chemical properties, as well as the implementation of appropriate engineering measures to ensure safe and reliable operation.

3. Risk Analysis

The vessel is a pre-designed LNG-fueled ship equipped with main propulsion and power generation systems, including one main engine, five (5) generators, and auxiliary boilers. It measures approximately 400 meters in length and 60 meters in breadth, and is designed to accommodate 30 regular crew members, with an additional six (6) crew members assigned for Suez Canal transits.

The objective of the HAZID study is to systematically identify potential hazards associated with the application of B100 biofuel in ship operations and to develop additional safety measures and recommendations to ensure safe and reliable performance. To support these objects, KR organized a workshop involving industry stakeholders and experts in design, engine and fuel systems of commercial ships. Many of the participants represented organizations such HMM, HD KSOE, HD HHI-EMD, Everllence, GS Caltex and SAMGONG.

The analysis covers the ship’s overall design concept, with hazard identification performed by dividing the ship's systems into functional nodes to increase analysis efficiency and maintain focused discussions. The study focuses on systems that are closely related to the application of B100 fuel, while systems common to conventional fossil fuel-powered vessels are excluded, as their design and operation are considered sufficiently established.

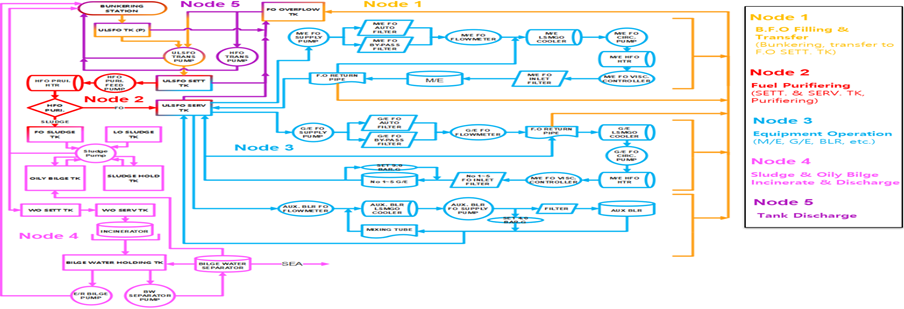

The workshop adopted a structured approach and divided the target system into the following five (5) functional nodes, each addressed through independent HAZID discussions. Refer to Figure 1 for additional details.

- Node 1 – B.F.O Filling & Transfer

- Node 2 – Fuel Purification

- Node 3 – Equipment Operation

- Node 4 – Sludge & Oily Bilge Incineration & Discharge

- Node 5 – Tank Discharge

[Figure 1] System Nodes for HAZID

4. Conclusion

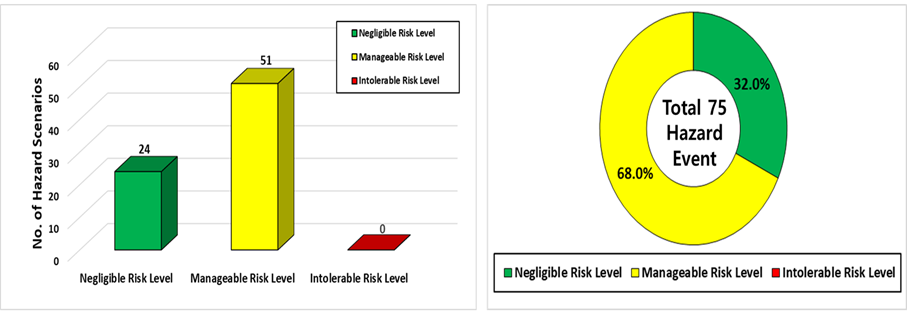

In this HAZID study, various hazards and hazardous events were systematically identified through workshop discussions. A hazardous event presents a potential accident scenario arising from a specific hazard, allowing for a clear understanding of the causal relationships and contributing factors.

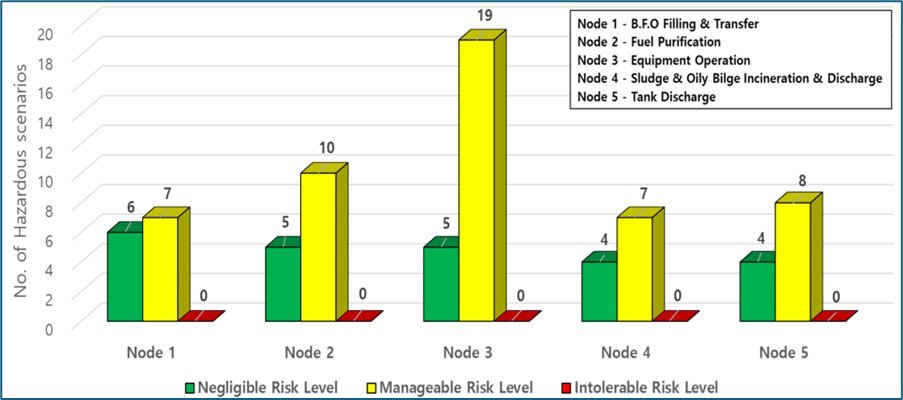

During the workshop, the safety devices and systems already incorporated into the design and operational plan for the application of B100 fuel on a 24,000 TEU-class container ship has been reviewed, along with additional safety measures and recommendations to further reduce risk. The results of the risk analysis for this system are summarized in [Figure 2] and [Figure 3].

[Figure 2] Hazard Identification Overall Results

[Figure 3] Risk Level Overall Results by System Node