-

- Notice for Amendments to KR Classification Technical Rules (Guidance Relating to the Rules for the Classification of Steel Ships Pt 8)

- Notice for Amendments to KR Classification Technical Rules (Guidance Pt.1 Annex 1-1 and Pt.3 Annex 3-6)

- Establishment of the “Guidelines of Local PWHT for Independent Type C Tank”

- NCSR 12 - News Brief

- [2025-IMO-07] Considerations for Compliance with the Hong Kong Convention (HKC)(Rev.2).

- Notice for Amendments to KR Classification Technical Rules (Guidance Relating to the Rules for the Classification of Steel Ships Pt 8)

- Notice for Amendments to KR Classification Technical Rules (Guidance Pt.1 Annex 1-1 and Pt.3 Annex 3-6)

- Establishment of the “Guidelines of Local PWHT for Independent Type C Tank”

- NCSR 12 - News Brief

- [2025-IMO-07] Considerations for Compliance with the Hong Kong Convention (HKC)(Rev.2).

-

- Notice for Amendments to KR Classification Technical Rules (Guidance Relating to the Rules for the Classification of Steel Ships Pt 8)

- Notice for Amendments to KR Classification Technical Rules (Guidance Pt.1 Annex 1-1 and Pt.3 Annex 3-6)

- Establishment of the “Guidelines of Local PWHT for Independent Type C Tank”

- NCSR 12 - News Brief

- [2025-IMO-07] Considerations for Compliance with the Hong Kong Convention (HKC)(Rev.2).

KANG Soomin, Alternative Fuel Technology Research Team

1. Background

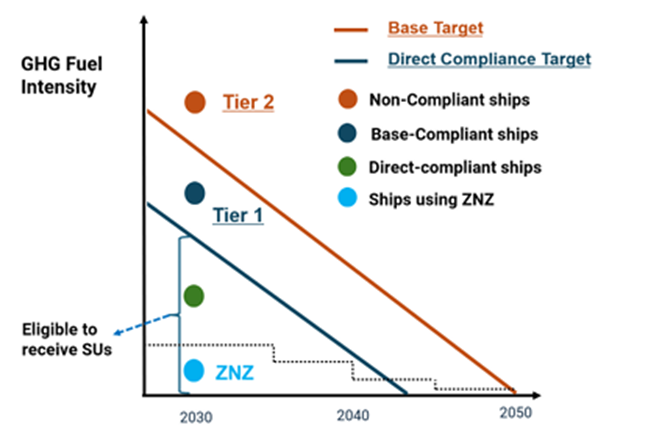

At its 80th session of the Marine Environment Protection Committee (MEPC) in July 2023, the International Maritime Organization (IMO) adopted a reduction strategy to achieve net zero greenhouse gas emissions by 2050. To achieve GHG net-zero, the 83rd MEPC approved amendments to MARPOL Annex VI on IMO mid-term measures. Regarding the IMO medium-term measures, ships are categorized into Non-Compliant ships, Base-Compliant ships, Direct-compliant ships, and Ships using ZNZ (Zero and Near Zero) according to GFI (Greenhouse gas Fuel Intensity), and the purchase of Remedial Units is required depending on the degree of compliance with the target.

In addition, Ships using zero or near-zero GHG fuels and technologies can receive incentives to compensate for the capital expenditure put into new building construction and the price gap between alternative fuels and fossil fuels. As a result, the IMO's medium-term measures urge a transition from conventional fossil fuels to low- and zero-carbon fuels.

Figure 1. Medium-term actions to reduce GHG emissions from international shipping

Ammonia is a zero-carbon fuel that does not emit carbon dioxide during combustion and can be used as a main fuel in engines. Therefore, many engine manufacturers are developing ammonia engines. Ammonia is the most efficient method for hydrogen storage and transportation on a large scale because its hydrogen storage capacity per volume is greater than that of liquefied hydrogen, LOHC, and methanol, and it has the advantage that ammonia can be converted to hydrogen for use in fuel cells at the same time as it is transported.

Ammonia is a toxic substance and exposure to humans can cause skin irritation, breathing difficulties, eye irritation, and in severe cases, death from respiratory arrest. In order to provide safety standards for ammonia-fueled ships, the IMO developed an interim safety guideline covering general and functional requirements for ammonia-fueled ships at CCC 10th, which was approved by MSC 109th. The guidelines specify the requirements for ammonia detection and release mitigation system for ammonia fuel applications.

As a result, it is essential to develop an ammonia detection system capable of identifying leaks at an early stage on ammonia-fueled ships, as well as an ammonia release mitigation system that can safely handle ammonia released from the fuel system. Therefore, performance evaluation facilities was established at the Korea Register of Shipping Green ship Equipment Testing and Certification Center (hereinafter referred to as ‘TCC’) to evaluate a leakage ammonia detection and release mitigation system, which is required as ammonia fuel is applied to ships.

2. Establishment of performance evaluation system for leakage

ammonia detection and ammonia release mitigation system

2.1 Establishment of performance evaluation system for leakage ammonia detection

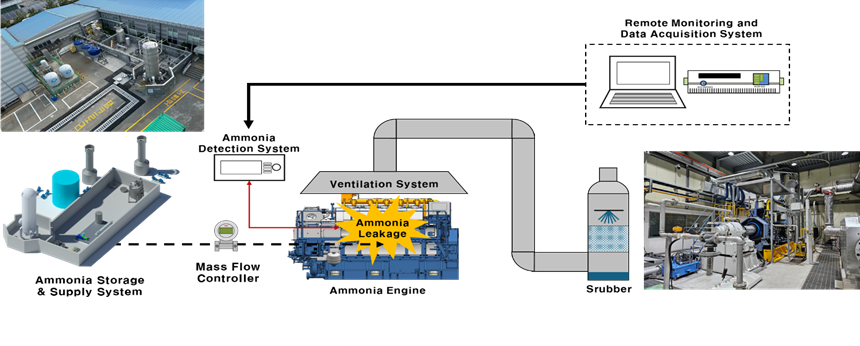

Recently, the TCC established an ammonia fuel storage and supply system. The established facilities enable the simultaneous supply of high-pressure liquid ammonia and low-pressure gaseous ammonia to the ammonia engine laboratory. Utilizing these facilities, a Mass Flow Controller (MFC) was installed in the laboratory to simulate ammonia leakage for the purpose of conducting performance evaluations of the ammonia detection system.

The MFC enables for the simulation of ammonia leakage in both liquid and gaseous states, and enables precise control over the leakage rate and location. To ensure safe performance evaluation, a remote monitoring system was established to observe ammonia leakage scenarios, along with a data acquisition system capable of collecting leakage concentration data in real time.

Additionally, a hood was installed on top of the laboratory allow for the overall ventilation of the leaked ammonia. A local ventilation system was also installed to selectively ventilate ammonia at the leakage points. Furthermore, to meet the ammonia emission standards and ensure a safe testing environment during the performance evaluation, an ammonia scrubber was established.

Figure 2. Schematic Diagram of the Performance Evaluation for Ammonia Detection Systems

2.2 Establishment of performance evaluation system for ammonia release mitigation systems

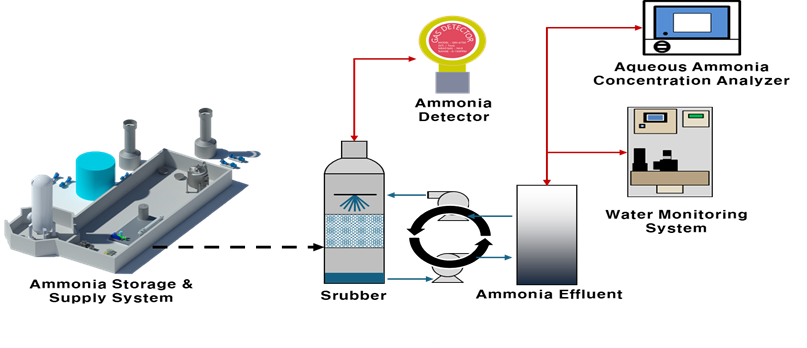

The interim guidelines for ammonia-fueled ships require the installation of an ammonia release mitigation system capable of handling ammonia releases from fuel piping purging and pressure relief valves. According to the regulations, the concentration of ammonia treated by such systems must be limited to below 110 ppm.

Among the ammonia release mitigation systems, scrubbers are already widely applied in other industries and are gaining attention as an ammonia release mitigation system due to their ease of application on ships. Accordingly, TCC has established performance evaluation facilities for ammonia scrubbers. The performance evaluation is based on monitoring the ammonia concentration released into the atmosphere through an ammonia scrubber. The system includes ammonia detectors, pH measuring devices for the ammonia effluent, and equipment capable of real-time measurement of ammonia concentration in the ammonia effluent.

Figure 3. Schematic Diagram of the Performance Evaluation for Ammonia Release Mitigation Systems

3. Summary and further plan

TCC has conducted and completed research on the development of key technologies for marine engines using ammonia fuel by building an ammonia storage and supply system. In connection with the performance evaluation facilities of the established ammonia detection and release mitigation system, further research will be carried out to develop and support safety technologies for the application of ammonia fuel. In addition, when absorption ammonia release mitigation systems are applied to treat ammonia emitted from ammonia-fueled ships, ammonia effluent is generated, but there are no international guidelines for managing ammonia effluent.

In this regard, TCC plans to conduct research on ammonia effluent management strategies based on the established ammonia release mitigation system testing facilities, and to utilize the research findings in the development of guidelines for ammonia effluent management.